-

Články

- Vzdělávání

- Časopisy

Top články

Nové číslo

- Témata

- Kongresy

- Videa

- Podcasty

Nové podcasty

Reklama- Kariéra

Doporučené pozice

Reklama- Praxe

USING PVDF FILMS AS FLEXIBLE PIEZOELECTRIC GENERATORS FOR BIOMECHANICAL ENERGY HARVESTING

In this paper, a commercial polymeric piezoelectric film, the polyvinylidene fluoride (PVDF) was used to harvest electrical energy during the execution of five locomotion activities (walking, going down and up the stairs, jogging and running). The PVDF film transducer was placed into a tight suit in proximity of four body joints (shoulder, elbow, knee and ankle). The RMS values of the power output measured during the five activities were in the range 0.1 – 10 µW depending on the position of the film transducer on the body. This amount of electrical power allows increasing the operation time of wearable systems, and it may be used to prolong the monitoring of human vital signals for personalized health, wellness, and safety applications.

Keywords:

human body, daily activities, elastic fabric, nanogenerators

Authors: Antonino Proto 1,2; Karel Vlach 2; Silvia Conforto 1; Vladimir Kasik 2; Daniele Bibbo 1; David Vala 2; Ivan Bernabucci 1; Marek Penhaker 2; Maurizio Schmid 1

Authors place of work: Department of Engineering, University of Roma Tre, Rome, Italy 1; Department of Cybernetics and Biomedical Engineering, VSB-Technical University of Ostrava, Ostrava-Poruba, Czech Republic 2

Published in the journal: Lékař a technika - Clinician and Technology No. 1, 2017, 47, 5-10

Category: Původní práce

Summary

In this paper, a commercial polymeric piezoelectric film, the polyvinylidene fluoride (PVDF) was used to harvest electrical energy during the execution of five locomotion activities (walking, going down and up the stairs, jogging and running). The PVDF film transducer was placed into a tight suit in proximity of four body joints (shoulder, elbow, knee and ankle). The RMS values of the power output measured during the five activities were in the range 0.1 – 10 µW depending on the position of the film transducer on the body. This amount of electrical power allows increasing the operation time of wearable systems, and it may be used to prolong the monitoring of human vital signals for personalized health, wellness, and safety applications.

Keywords:

human body, daily activities, elastic fabric, nanogeneratorsIntroduction

The recent trend for bioengineers who are studying the safety and health of human beings is to develop compact and portable measurement systems able to provide information about the vital parameters of people [1–5].

Wearable sensor nodes are a modern way to monitor the health status of human beings, as they are practical, comfortable and not invasive [6–10]; they are also able to communicate with processing devices, such as PCs, smart-phones or radio stations [11].

If one is interested in long-term monitoring of biosignals, the main obstacle of this frontier is the power source of wearable sensor nodes, as it limits their use due to the short battery life. Increasing battery life can be done at the expense of greater sizes, thus making it difficult to have the sensor comfortable for users. A method for fixing this issue is to focus on the energy harvesting from environmental sources, to extend the operating time of devices, or even making them autonomous [12]. The most accessible energy sources in the environment are light, thermal gradients, radio frequency waves and mechanical vibrations. Our goal is to investigate the possibility to recover energy by exploiting the generated mechanical power from the human body while performing locomotion activities, i.e. the biomechanical energy harvesting. Thad Starner studied it at first, in 1996 [13]: he pointed out that a 68-kg healthy man, walking at 2 steps per second, can generate 67 W mechanical power by the action of the heel strike through 5 cm height. Starner hypothesized a percentage value of 10% for the convertible power from mechanical to electrical, simply by using an electromechanical generator placed into shoes. Although electromechanical systems can reach high values of power generated (for instance the biomechanical energy harvester “SPaRK” used by US Army), they are not suitable for developing wearable and comfortable biomechanical harvesters, due to their big sizes.

In order to overcome this problem for designing wearable biomechanical harvesters, the main suitable transducers are the electromagnetic, electrostatic and piezoelectric ones [14]. The first one generates low level of voltage output, and the second one requires separate voltage source to operate [15]. Therefore, we focus on piezoelectric transducers.

Piezoelectric transducers convert mechanical deformations into measurable electrical energy, which causes the direct piezoelectric effect. Thus, the piezoelectric transducers can produce electrical energy from the biomechanical body movements.

In the current scientific literature, we denote several examples of biomechanical energy harvesters; they are divided based on the placement of the harvester on different body parts. For instance, Renaud et al. [16] designed a piezoelectric transducer mounted on the human wrist able to generate up to 40 µW/cm3, theoretically. Again, Jung et al. [17] developed a curved piezoelectric generator placed into a watchstrap able to produce 3.9 mW/cm2 of instantaneous power density from the low frequency, such as the body movement frequencies. Regarding the possibility to integrate the piezoelectric harvester into a shoe insole, Shenck and Paradiso [18] proposed the most important work in the current literature. They designed a system composed by a flexible piezoelectric stave, placed under the insole and a hard dimorph piezoelectric element placed into the insole. The system could harvest up to 9.7 mW at 0.9 Hz of walking pace. Concerning the possibility of harvesting the energy through a backpack, Feenstra et al. [19] developed a system by replacing the strap buckle with a mechanically piezoelectric stack actuator, which generates 0.4 mW electrical power from the differential forces between the wearer and the pack. Pozzi et al. [20] proposed a plucked piezoelectric bimorphs for knee-joint energy harvesting. The system had the potential to produce a sustained power of several milliwatts during walking. In addition, Shukla and Bell [21] reported a novel concept of harvesting the energy from low frequency and low force of human gait movement, from a device attached at the waistline. The maximum power output for this system was nearly 300 µW.

All these biomechanical energy-harvesting systems are rigid and they are not comfortable to be wear for the users. In order to achieve comfortable energy harvesting devices for human beings we need to investigate the feasibility for placing ultra-flexible piezoelectric harvesters on body surface.

Thus, the polymer-based piezoelectric materials, such as the polyvinylidene fluoride (PVDF) or its similar copolymer, the poly(vinylidene fluoride-cotrifluoroethylene) (P(VDF-TrFe)), are used for piezoelectric applications because of their advantageous properties of flexibility, adequate mechanical strength, ease of processing and high chemical resistance. For instance, Chang et al. [22] have demonstrated PVDF piezo-fibers that are directly written onto flexible plastic substrates, thus making foldable the whole structure.

Therefore, in the proposed work, we use a PVDF film transducer for harvesting the biomechanical energy from common human locomotion activities, such as walking, going up and down the stairs, jogging and running. The folding behavior of the transducer allows following all movements of the body joints, without feeling discomfort for the wearers. Thus, we tested the PVDF transducer to find out the power output while performing biomechanical movements.

Materials and Methods

Properties of PVDF film transducer

The PVDF film transducer - LDT4-028k - (www.meas-spec.com) [23] was chosen for tests, in order to achieve the desired flexibility for the wearable energy harvesting system. It is formed as follow: a 125 µm polyester layer is laminated to a 28 µm PVDF film element, and another 52 µm polyester layer is covered on it to protect the PVDF layer.

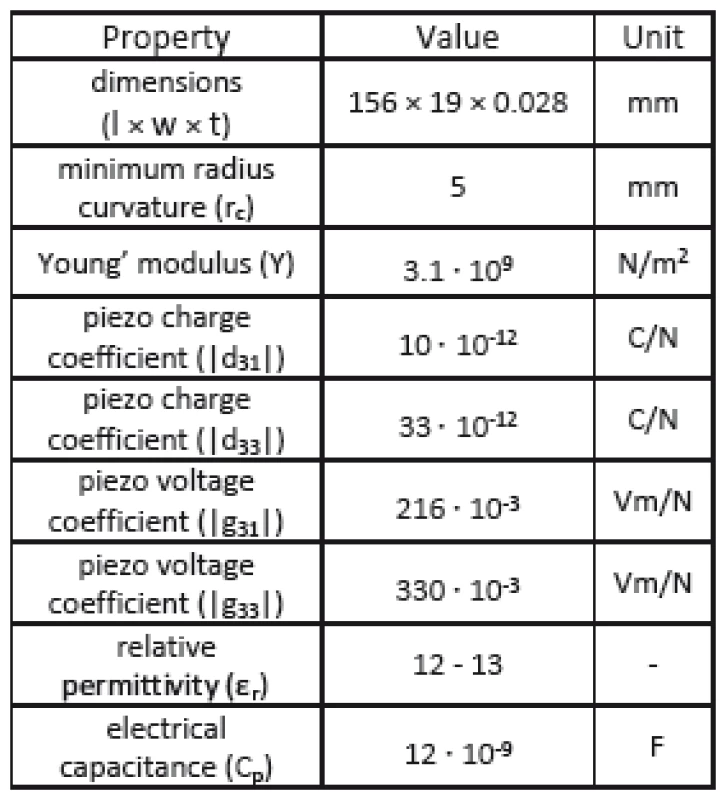

In Tab. 1 we summarized the electromechanical properties of the LDT4-028k film transducer.

Tab. 1. The main electromechanical properties of the LDT4-028k transducer

There are many factors that govern the piezoelectric effect for the mechanical-to-electrical energy conversion: the piezoelectric properties of the material, the size and shape of the film, the direction of mechanical excitation, and the electrical response of the film. Particularly, the coefficient d3n and g3n (shown in Tab. 1) are the charge and voltage piezoelectric coefficients, respectively, and they possess two subscripts. The former refers to the electrical axis while the latter refers to the mechanical axis. Accordingly, and with reference to Fig. 1, the electrical axis is always ‘3’ (thickness axis) and the mechanical axis can be either ‘1’ (length axis), ‘2’ (width axis) or ‘3’ since the stress can be applied to any of these axes.

These piezoelectric film transducers generate high voltage output values when the mechanical deformation occurs along the length direction, '1'; the reason for that is purely geometrical, since the cross-sectional area is much smaller than the surface area.

Accordingly, every energy harvesting application related to the movements of the human segments linked to the body joints must be dominated by deformations in the length direction of the film transducer and then, under conditions to approach an open-circuit voltage, the theoretical generated voltage output caused by mechanical deformations of the transducer can be calculated by the following equation [24]:

where “t” is the film material thickness, “ε” is the absolute permittivity of the material, “d31” is the charge piezoelectric film coefficient, “Y” is the Young’s modulus and “Δl/l” is the elongation of the PVDF film transducer.

Fig. 1: Numerical classification of axes of the PVDF film transducer: 1-length direction (l), 2-width direction (w) and 3-thickness direction (t).

Elastic cotton suit for on-body PVDF positioning

The LDT4-028k film transducer has to be placed directly onto the skin in order to transduce the motions of the joints in the most appropriate way. Thus, an elastic cotton suit was made to ensure sufficient adjacency to the body.

Fig. 2: The blue suit with the green slots and a green betl: 1-ankle plantar position, 2- elbow pit position, 3- posterior knee position and 4-armpit position.

During the tests, the transducer was placed in the slots of the suit, attached to each individual joint. Fig. 2 shows the blue suit with the green slots, and a green belt that was used to acquire the power generated from the ankle rotations. The positions for the film transducer on the suit were chosen according to the value of its folding parameter, the minimum radius curvature. The LDT4-028k film transducer is truly flexible and therefore was placed in the inner parts of the suit where the joints are at the maximum bending angle: the ankle plantar area, the elbow pit, the posterior knee and the armpit.

Electrical measurement circuit

In order to study the purely electrical behavior of the film transducer, the equivalent circuit for the PVDF element is formed by a current generator in parallel with a capacitance. As it is shown in Fig. 3, to find out the power generated by the mechanical deformation of the PVDF film transducer, a resistive load was attached in parallel with the PVDF [25]. The values of the resistive loads were carefully established in a previous work [26], made from our group.

Fig. 3: Measurement circuit and <sub>Vout</sub> equation.

The values of the voltage output were measured and acquired by the NI USB-6210 data acquisition system (DAQ), National Instruments; also, a voltage divider circuit was used as the input stage of the DAQ in order to avoid the problem of saturation given by the range of voltage values at the input stage of the DAQ.

Testing and Evaluation

Three healthy male volunteers (age: 34 ± 5 year; body weight: 76 ± 4 kg; height: 175 ± 5 cm) were recruited to perform five locomotion activities: walking, going up and down the stairs, jogging and running, mentioned before. The measuring time of walking, going up and down the stairs was one minute for each test, while the measuring time of the jogging activity was twenty seconds and for the running activity eight seconds.

The angle values for the range of motion of the body joints were measured and reported in a previous work made from our group, as well as the frequency values of each performed activity [26].

The acquired experimental data, based on the five performed activities, were elaborated to obtain the root mean square (RMS) values of the power generated through the biomechanical motions of the body joints.

The results of the RMS power values, plus the values of the calculated standard deviations were compared, based on the location of the film transducer onto the body.

Fig. 4 shows the comparison of the power generated by the mechanical deformation of the LDT4-028k film transducer, placed on each joint, during the performed five activities.

Fig. 4: Comparison of the power generated by the LDT4-028k film transducer, placed on each joint, during the performed five activities. Error bars represent standard deviations.

As it can be clearly seen in Fig. 4, the joint positions such as elbow, shoulder and ankle led to very similar RMS power values for the running activity (~5 µW). Out of these three joint positions, walking, going up and down the stairs led to very similar RMS power values for the shoulder and elbow joints: ~0.25 µW, while the ankle joint produces ~0.65 µW. Again, out of these three joint positions, the jogging activity produces ~3 µW for the ankle joint, ~2 µW for the elbow joint, and ~1 µW for the shoulder joint. Finally, the knee joint position represents the best location for an energy harvesting system, in terms of generated power output while performing common human locomotion activities. As per walking, going up and down the stairs, the generated RMS values of power output are ~2 µW; ~4 µW for the jogging activity and ~9 µW for the running activity.

Discussion

The best results in terms of generated power output were obtained at the level of the knee joint, since the value of the range of motion on this joint is higher than the same range of motion values of the other joints. As it can be clearly seen from the results shown in Fig. 4, the RMS values of the generated power are in the range 0.1–10 µW, which is a typical power range for supplying energy to generic ultra-low power integrated circuits for biomedical applications [27–29].

Regarding the influence of the activity kind on the amount of power that can be harvested, results are in line with the hypothesis that both the amplitude of activity (assented by the range of motion), and cadence (assented by the activity frequency) play an important and synergistic role. It is not strange that activities with higher values of both range of motion and frequency (running, and to a lesser extent, jogging and walking downstairs) provide higher values in terms of power than those obtained while walking or ascending the stairs.

The data results achieved in this work, concerning the values of the power output generated from the PVDF film during the locomotion activities, are very similar with the data results of the piezoelectric wearable systems for biomechanical energy harvesting found in the current scientific literature and reported as follows. Zhang et al. [30] developed a fabric nanogenerator able to produce 10.02 nW when it is attached on an elbow pad and bent by human arms. Yang and Yun [31] prepared three fabrics in the form of band for wearing it on elbow joint, measuring 0.21 mW for a bending velocity of 5 rad/s. Again, Hwang et al. [32] developed a thin piezoelectric harvester on a flexible plastic substrate, able to generate a power density of about 7 mW/cm3 by bending the finger.

Thus, the data of power output harvested by our system may represent an added value to the results of the current scientific literature, which represent values of the power output generated only from individual body movements.

By considering wearability and comfort of the proposed system, the chosen PVDF film transducer has allowed easy integration into the cotton suit, since it is very thin and flexible. The movements of the limbs during the performed activities were not obstructed by the film transducer, thus making the system comfortable for the users. However, further tests should be performed for testing the reliability of the system while performing long-time activities.

Finally, we note that the basic components needed for developing piezoelectric generators, for the field of biomechanical energy harvesting, are flexible substrates and electrodes that can maintain their original mechanical and electrical properties after bending or stretching of the structure.

Conclusion

In this paper, a PVDF piezoelectric film transducers – LDT4-028k – was placed inside a tight suit in proximity to the main human body joints, such as shoulder, elbow, knee and ankle, in order to harvest the energy generated by locomotion activities in the form of casual walking, going up and down the stairs, jogging and running. In order to work at its best, it is very important for a biomechanical energy harvesting system to use a flexible piezoelectric transducer to ensure as close contact as possible between the transducers and the skin; therefore, a special manufactured body suit was produced to be worn during the performed activities.

When examining the power output measured during the five common locomotion activities, the values of the power output was in the range 0.1–10 µW, depending by the position of the transducer onto the body. The reported study should be encourage the development of biomechanical energy harvesting structures, which can be directly integrated in general wearable systems for the bio-signals monitoring.

Acknowledgement

This work was supported and financed by project SV4507741/2101 ‘Biomedical Engineering systems XIII' and the research project of The Czech Science Foundation (GACR) No. 17-03037S, and Italian Ministry of Education, University and Research. The suit was made by 3M MANIFATTURE S.R.L., Pomarico (MT) 75016, Basilicata, Italy.

Ing. Antonino Proto, Ph.D.

Departm. of Engineering, Roma Tre University

Via Vito Volterra 62, Building B, Room 3.4

Rome, IT-00146

Departm. of Cybernetics and Biomedical Engineering

VSB-Technical University of Ostrava

Ul. 17. listopadu 15, Building FEI, Katedra 450

Ostrava-Poruba,

CZ-70833

E-mail: proto.perri.antonino@gmail.com

Zdroje

[1] Bonato, P.: Wearable Sensors and Systems From Enabling Technology to Clinical Applications. Ieee Engineering in Medicine and Biology Magazine, vol. 29, no. 3, 2010, p. 25–36.

[2] Vavrinský, E., et al. Document Monitoring of EMG to force ratio using new designed precise wireless sensor system. Lékař a Technika, vol. 44, no. 3, 2014, p. 17–22.

[3] Jagelka, M., et al. Implementation of pulse oximetry measurement to wireless biosignals probe. Lékař a Technika, vol. 44, no. 3, 2014, p 37–40.

[4] Jagelka, M., et al. Preliminary testing of flexible electrodes for biosignal measurement: abrasion resistance. Lékař a Technika, vol. 45, no. 1, 2015, p. 16–20.

[5] Proto, A., et al. Wearable PVDF transducer for biomechanical energy harvesting and gait cycle detection. Proceedings of IEEE EMBS Biomedical Engineering and Sciences Conference, 2016, p. 62–66.

[6] Fida, B., et al. The effect of window length on the classification of dynamic activities through a single accelerometer. Proceedings of the IASTED International Conference Biomedical Engineering, vol. 2325, 2014, p. 123–127.

[7] Karchňák, J., et al. Utilizing of mems sensors in rehabilitation process. Lékař a Technika, vol. 44, no. 3, 2014, p 12–16.

[8] Caramia, C., et al. Spatio-temporal gait parameters as estimated from wearable sensors placed at different waist levels. Proceedings of IEEE EMBS Biomedical Engineering and Sciences Conference, 2016, p. 727–730.

[9] Fida, B., et al. Real time event-based segmentation to classify locomotion activities through a single inertial sensor. Proceedings of the 5th EAI International Conference on Wireless Mobile Communication and Healthcare, 2015, pp. 104–107.

[10] Proto, A. et al. A new microcontroller-based system to optimize the digital conversion of signals originating from load cells builtin into pedals. Proceedings of IEEE 2014 Biomedical Circuits and Systems Conference, 2014, p. 300–303.

[11] Poon, C.C.Y., et al. Body Sensor Networks: In the Era of Big Data and Beyond. IEEE reviews in biomedical engineering, vol. 8, 2015, p. 4–16.

[12] Gambier, P., et al. Piezoelectric, solar and thermal energy harvesting for hybrid low-power generator systems with thinfilm batteries. Measurement Science and Technology, vol. 23, no. 1, 2012.

[13] Starner, T. Human-powered wearable computing. Ibm Systems Journal, vol. 35, no. 3-4, 1996, p. 618–629.

[14] Vullers, R.J.M., et al. Micropower energy harvesting. Solid-State Electronics, vol. 53, no. 7, 2009, p. 684–693.

[15] Roundy, S., et al. A study of low level vibrations as a power source for wireless sensor nodes. Computer Communications, vol. 26, no. 11, 2003, pp. 1131–1144.

[16] Renaud, M., et al. Scavenging energy from human body: Design of a piezoelectric transducer. Transducers '05, Digest of Technical Papers, 2005, vol. 1-2, p. 784–787.

[17] Jung, W.-S., et al. Powerful curved piezoelectric generator for wearable applications, Nano Energy, 2015, vol. 13, p. 174–181.

[18] Shenck, N.S. and Paradiso, J.A. Energy scavenging with shoemounted piezoelectrics, Ieee Micro, 2001, vol. 21, no. 3, p.

30–42.

[19] Feenstra, J., et al. Energy harvesting through a backpack employing a mechanically amplified piezoelectric stack, Mechanical Systems and Signal Processing, 2008, vol. 22, no. 3, p. 721–734.

[20] Pozzi, M. and Zhu, M. Plucked piezoelectric bimorphs for kneejoint energy harvesting: modelling and experimental validation, Smart Materials & Structures, 2011, vol. 20, no. 5.

[21] Shukla, R. and Bell, A.J. PENDEXE: A novel energy harvesting concept for low frequency human waistline, Sensors and Actuators a-Physical, 2015, vol. 222, p. 39–47.

[22] Chang, C., et al. Direct-Write Piezoelectric Polymeric Nanogenerator with High Energy Conversion Efficiency. Nano Letters, vol. 10, no. 2, 2010, p. 726-731.

[23] Piezo Sensor—LDT Series. Available online: http://www.measspec.com/product/t_product.aspx?id=2484.

[24] Piezo Technical Manual. Available online: http://www.measspec.com/downloads/Piezo_Technical_Manual.pdf.

[25] Ottman, G.K., et al. Adaptive piezoelectric energy harvesting circuit for wireless remote power supply, IEEE Transactions on Power Electronics, 2002, vol. 17, p. 669–676.

[26] Proto, A., et al. Measurements of Generated Energy/Electrical Quantities from Locomotion Activities Using Piezoelectric Wearable Sensors for Body Motion Energy Harvesting, Sensors, 2016, vol. 16, n. 4, p. 524.

[27] Meindl, J.D.: Low-power microelectronics: retrospect and prospect, Proceedings of the Ieee, 1995, vol. 83, p. 619–635.

[28] Chandrakasan, A.P., et al. Ultralow-power electronics for biomedical applications, Annual Review of Biomedical Engineering, 2008, vol. 10, p. 247–274.

[29] Proto, A.: Nanogenerators for Human Body Energy Harvesting. Trends in Biotechnology, Article in Press.

[30] Zhang, M., et al. A hybrid fibers based wearable fabric piezoelectric nanogenerator for energy harvesting application, Nano Energy, 2015, vol. 13, pp. 298–305.

[31] Yang, B. and Yun, K.-S.: Piezoelectric shell structures as wearable energy harvesters for effective power generation at low-frequency movement, Sensors and Actuators a-Physical, 2012, vol. 188, p. 427–433.

[32] Hwang, G.-T., et al. Flexible Piezoelectric Thin-Film Energy Harvesters and Nanosensors for Biomedical Applications, Advanced Healthcare Materials, 2015, vol. 4, no. 5, p. 646–658.

Štítky

Biomedicína

Článek vyšel v časopiseLékař a technika

2017 Číslo 1-

Všechny články tohoto čísla

- THE EFFECT OF FLUID ACCUMULATION IN STOMACH ON ELECTRICAL IMPEDANCE TOMOGRAPHY IMAGE OF LUNGS

- EFFECT OF STERILIZATION ON MECHANICAL PROPERTIES OF COLLAGEN-BASED COMPOSITE TUBES

- BIOFEEDBACK AS A NEUROBIOMECHANICAL ASPECT OF POSTURAL FUNCTION

- THE USE OF NONINVASIVE DIAGNOSTIC METHODS IN THE ASSESSMENT OF POSTURAL CHANGES IN UNIVERSITY STUDENTS

- USING PVDF FILMS AS FLEXIBLE PIEZOELECTRIC GENERATORS FOR BIOMECHANICAL ENERGY HARVESTING

- Lékař a technika

- Archiv čísel

- Aktuální číslo

- Informace o časopisu

Nejčtenější v tomto čísle- THE USE OF NONINVASIVE DIAGNOSTIC METHODS IN THE ASSESSMENT OF POSTURAL CHANGES IN UNIVERSITY STUDENTS

- BIOFEEDBACK AS A NEUROBIOMECHANICAL ASPECT OF POSTURAL FUNCTION

- USING PVDF FILMS AS FLEXIBLE PIEZOELECTRIC GENERATORS FOR BIOMECHANICAL ENERGY HARVESTING

- THE EFFECT OF FLUID ACCUMULATION IN STOMACH ON ELECTRICAL IMPEDANCE TOMOGRAPHY IMAGE OF LUNGS

Kurzy

Zvyšte si kvalifikaci online z pohodlí domova

Autoři: prof. MUDr. Vladimír Palička, CSc., Dr.h.c., doc. MUDr. Václav Vyskočil, Ph.D., MUDr. Petr Kasalický, CSc., MUDr. Jan Rosa, Ing. Pavel Havlík, Ing. Jan Adam, Hana Hejnová, DiS., Jana Křenková

Autoři: MUDr. Irena Krčmová, CSc.

Autoři: MDDr. Eleonóra Ivančová, PhD., MHA

Autoři: prof. MUDr. Eva Kubala Havrdová, DrSc.

Všechny kurzyPřihlášení#ADS_BOTTOM_SCRIPTS#Zapomenuté hesloZadejte e-mailovou adresu, se kterou jste vytvářel(a) účet, budou Vám na ni zaslány informace k nastavení nového hesla.

- Vzdělávání