-

Medical journals

- Career

A comparsion of the quality of dental crowns from TI-6AL-4V and cocr alloys made with SLM technology

Authors: Viktória Rajťúková 1; Alena Balogová 1; Teodor Tóth 1; Radovan Hudák 1; Jozef Živčák 1; Gabriela Ižáriková 2; Andrej Somoš 3; Mila Kovačevič 4

Authors‘ workplace: Department of Biomedical Engineering and Measurement, Faculty of Mechanical Engineering, Technical University of Kosice, Kosice, Slovakia 1; Department of Applied mathematics and Informatics, Faculty of Mechanical Engineering, Technical University of Kosice, Kosice, Slovakia 2; Louis Pasteur University Hospital, Department of Pneumology and Phtiseology, Kosice, Slovakia 3; Faculty of Medicine, University of Novi Sad, Novi Sad, Serbia 4

Published in: Lékař a technika - Clinician and Technology No. 1, 2018, 48, 22-28

Category: Original research

Overview

At present, dental replacements are more and more often being made with the use of additive manufacturing. In dentistry, selective laser melting (SLM), which enables the manufacturing of dental replacements from the alloys CoCr and Ti-6Al-4V, is the technology most used. With comparable costs for production, Ti-6Al-4V has significantly better biocompatibility, better mechanical properties and lower weight in comparison with an alloy from CoCr. The goal of the submitted study is a comparison of the production precision of dental crowns from CoCr alloy and Ti-6Al-4V alloy manufactured on a Mlab cusing R machine. For purposes of the study 30 crowns were manufactured from CoCr alloy and 30 from Ti-6Al-4V alloy on a Mlab cusing R machine, with the settings recommended by the manufacturer. After production the crowns were scanned using a Medit Identica dental scanner. The obtained data were subsequently modified and compared with a nominal CAD model in the Volume Graphics VGStudioMAX 2.2 software. The results are deviations on the level of 95% of coverage of the compared work with nominal geometry for all evaluated groups. The obtained deviations were subsequently processed statistically for the purpose of determining the statistical significance of the difference between the materials.

Keywords:

dental crowns, CoCr alloy, Ti-6Al-4V alloy, quality of production, SLM technologyIntroduction

Technology for the production of dental replace-ments and constructions over the past 30 years has rapidly developed and has done so mainly by the development of simulation [1–4], digitalization [5–7] and implementation of additive technologies [5–8]. The use of CAD/CAM systems in dentistry has led to the elimination of many manual procedures, to increased precision of dental replacements and constructions as well as to a reduction in production time [9]. Additive technologies were developed as an alternative to sub-tractive technology (milling) [10–13].

Additive technology offers a great many advantages versus subtractive or traditional methods of producing dental replacements. The first advantage is the possi-bility of also making geometrically more complex elements - partial prostheses as well as the controllabil-ity and speed of the production process. Another advantage is the possibility of products made from various materials and the possibility of achieving a product with the desired mechanical properties. The last advantage is the wide choice of additive technologies used in dentistry, among which is equipment from the companies Arcam (Sweden), Concept Laser (Germany), Renishaw (United Kingdom) [12], and SLM Solutions (Germany), SLM Realizer 2, MCP-HEK (SLM Tech Center, Borchen, Germany) [14, 15], PM 100 Dental System (Phenix Systems, Clermont - Ferrard, France) [16–20], Bego Medifacturing system (Bego Medical, Germany)

[21–23], Biomain AB (Helsingborg, Sweden) [24, 25], and EOSINT M250 Xtended (EOS, Munich, Germany) [26].The alloy CoCr is the most used material in dentistry, mainly due to its simple processing for dental technology. CoCr alloy is used in dentistry for the production of detachable partial prostheses, metal constructions, crowns and bridges [27–30]. The advantage of CoCr alloys is that they offer adequate material properties, including firmness, hardness, resistance to corrosion, a high modulus of elasticity and good electromechanical properties [30–33] and are also relatively inexpensive in comparison with alloys of gold and some fully ceramic materials [28, 30, 31, 34].

Alloys of Ti-6Al-4V used in medicine are distin-guished by excellent osseointegration, excellent resistance to corrosion, biocompatibility [8, 35, 36] and favourable mechanical properties in comparisons with alloys of chromium cobalt or stainless steel [27, 36–38]. They are used successfully in dentistry for the production of crowns and bridges or solid partial replacements [36, 39].

When casting alloys of Ti-6Al-4V problems arise due to the high affinity of smelted alloy, which leads to insufficient binding of ceramics to the titanium dental replacement and subsequently leads to clinical errors [27]. However, with the use of SLM technology the mentioned problems are eliminated, and Ti-6Al-4V alloy is beginning to soon be used in dentistry for the production of dental replacements [35, 37, 40–42].

The goal of the submitted study is a comparison of the production precision of dental crowns from CoCr alloy and Ti-6Al-4V alloy manufactured on a Mlab cusing R machine (Concept Laser, Germany). The idea is to introduce the use of titanium alloy into dental practice as a material with better properties than CoCr.

Methodology and measurement

The foundation for SLM technology is a 3D model of the dental replacement, which can be obtained by scanning of a dental stone model or by directly scanning the dental cavity with an intraoral scanner. The model is then subsequently modified in CAD software, the output of which is an *stl file. For preparation of the 3D model of a crown the CAMbrigde software (3Shape, Denmark) was used, in which the model of the crown is positioned, and the supporting structure is designed. After final modification a *cls file is generated, which is read into the software in the Mlab cusing R (Concept Laser, Germany) machine.

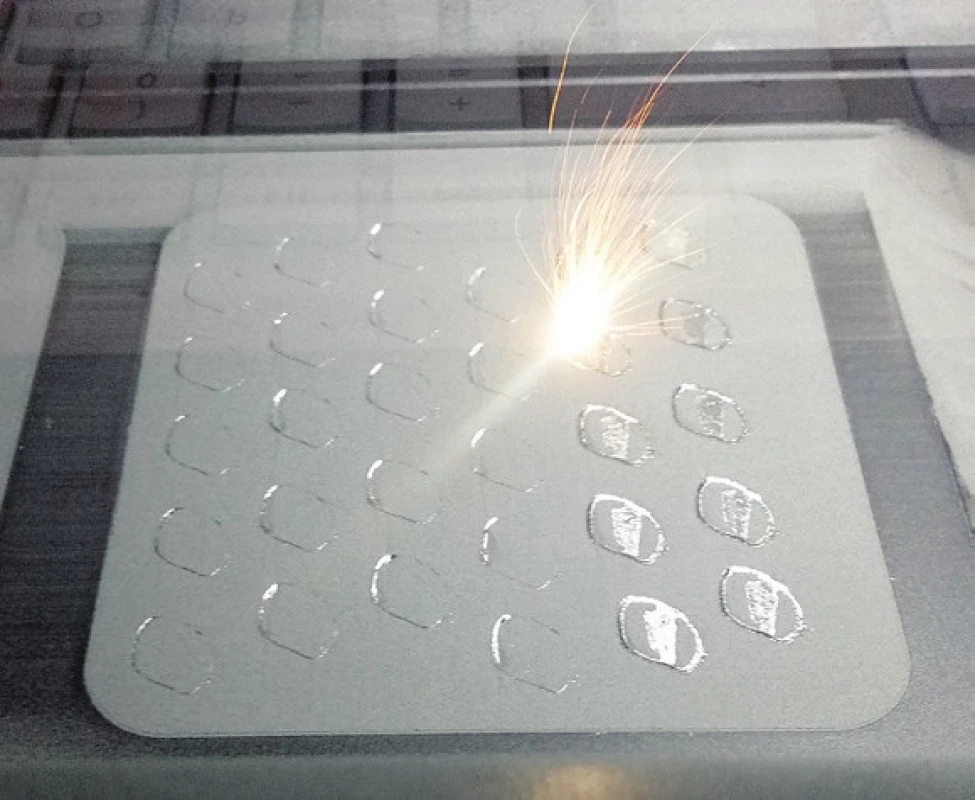

Subsequently, the production is initiated and after the production manufactured crowns (Fig. 1) are annealed and removed out of the building platform.

1. Production of dental crowns using SLM technology.

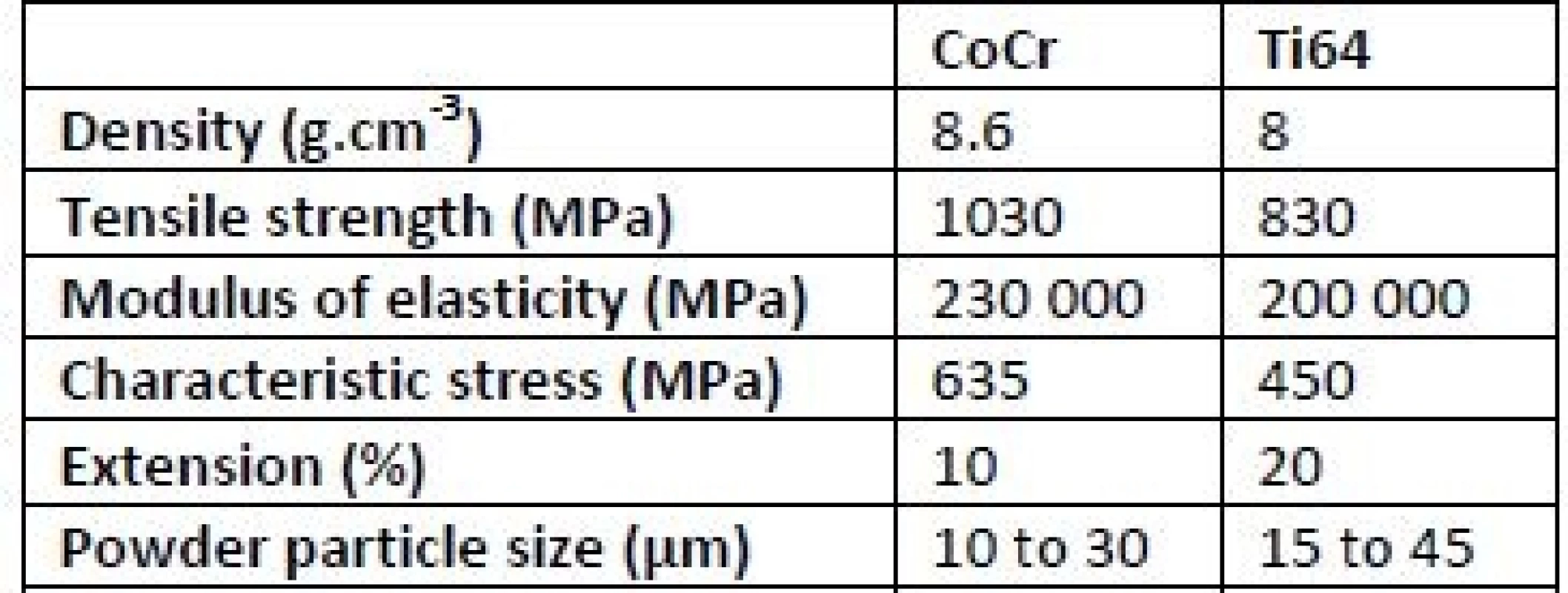

In the submitted study metal powders of the alloy CoCr remanium star CL (Dentaurum, Germany) marked as CoCr and the alloy Ti-6Al-4V (Grade 5) rematitan CL (Dentaurum, Germany) marked as Ti64, which are used for the production of dental replace-ments by SLM technology, were compared. Both alloys satisfy the standards EN ISO 9693/DIN and EN ISO 22674 (Table 1).

1. Mechanical properties of CoCr and Ti64.

The produced crowns were scanned with an Identica (Seoul, Korea) dental scanner, which uses white light for scanning. The scanner is primarily intended for scanning plaster models, the surface of which is matte and with a constant colouring. The surface of the produced crowns was shiny, so for this reason a chalk spray was used.

For further evaluation the interior surface of the crown was necessary to scan, which is also taken into account during its positioning in the dental scanner. Before the first scanning an internal verification of the function of the scanner was conducted using verification elements supplied by the manufacturer.

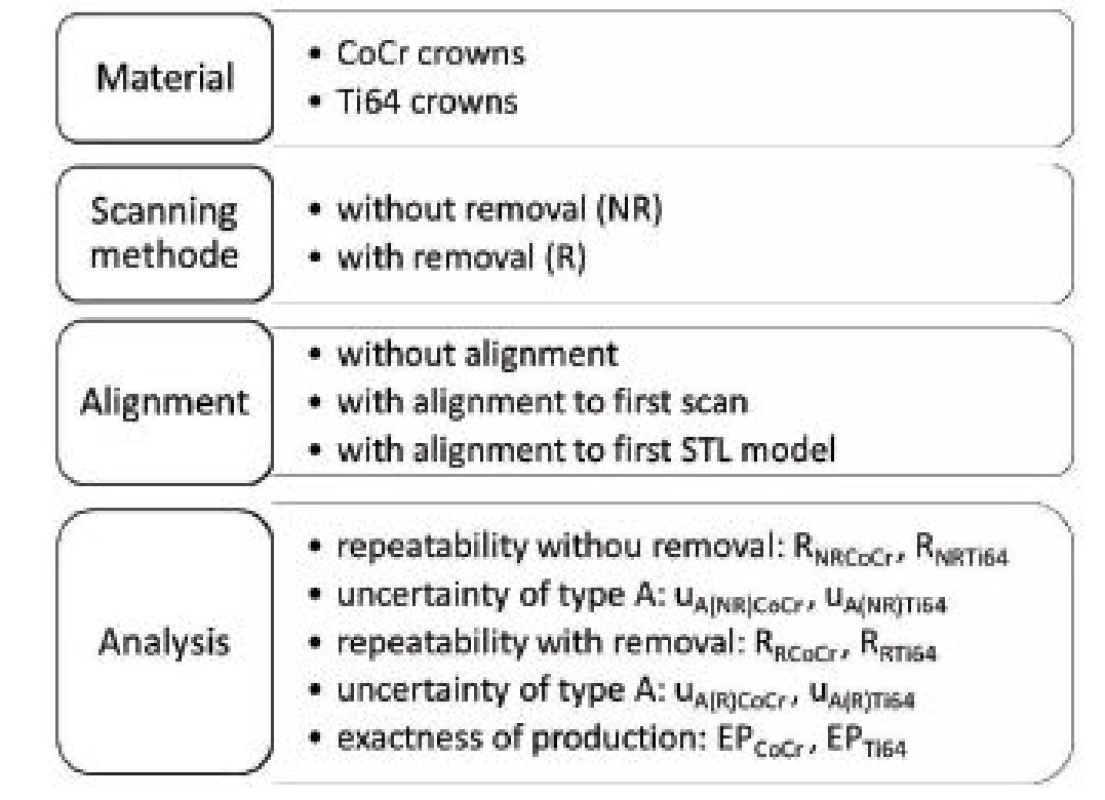

In the first step the process of scanning was verified. Because the scanned sample was not taken out, the influence of gripping the sample – the position of the sample in the detecting unit of the appliance – was eliminated from the process. Likewise, possible damage to the deposited layer of powdered chalk serving to dim the surface of the sample was thus avoided. The selected sample was scanned 30 times (nNR=30), without removal of the scanned crowns

(NR – not removal) which represents a set enabling the statistical processing of data. The individual scans were subsequently compared with the first scan.In the second step the influence of the positioning of the sample was also projected into the scanning results. The sample was not taken out of the detection unit because this could lead to damage of the dimming spray; the entire detecting unit was taken out. This process was repeated 30 times (nR=30) with removal of the scanned crowns out of the scanner (R - removal), the same as in the first case. The detecting unit is held in place in the scanner magnetically, and the shape of its base defines its position, and so it can be attached in only one position. The individual scans were sub-sequently compared with the first scan (Fig. 2).

2. Methodology for the evaluation of crowns.

All samples were scanned once for the process of analysing the data, and all the scans were performed on the same initial settings of the scanner with one internal verification.

All the acquired data was evaluated in the VGStudioMAX 2.2 software (Volume Graphics, Germany). The Nominal - Actual Comparison module was used for the analysis. With respect to the fact that each scan has its own coordinate system, it is usually not possible to compare two scanned samples directly. This statement does not apply for evaluation of the repeatability without retrieval of the scanned sample, because in this case the same position should be ensured for all scans.

Balancing of the assessed model consists in the first step of the Best-Fit method, which serves for a rough balancing of the actual and nominal geometry, and in the second step the reference positioning system (RPS) method, which serves for the fine positioning of the geometries. Reference points are placed on the surface of the nominal geometry excluding areas with possible extremes in the analyzed geometry (highlighted transitions of surfaces, corners etc.).

With respect to the fact that a common surface is involved, it was necessary to appropriately set the requirements for evaluation.

The result of the comparison is a deviation obtained with the set percentage conformity between the reference model and the compared work. In this case this method of evaluation is suitable because it provides information about the whole examined surface and not only locally, without possible consider-ation of the minimum and maximum deviations.

For the purpose of analysis of the acquired data a tolerance on the level of T = ±50 µm was selected for the deviation from the nominal geometry on the basis of the parameters of the production equipment.

The Nominal - Actual Comparison module provides as a result a deviation at each site of the examined geometry from the nominal geometry. In addition to this distribution of the deviation, it also gives the value of maximum deviation for the required percentage coverage and the opposite (e.g. for 95% percent of all deviations the maximum deviation is on the level of 0.05 mm, or 95% of the examined surface has a maximum deviation of 0.05 mm).

For the resulting analysis the condition of the maximum deviation with 95% coverage of the surface depending on the reference source was used.

Results

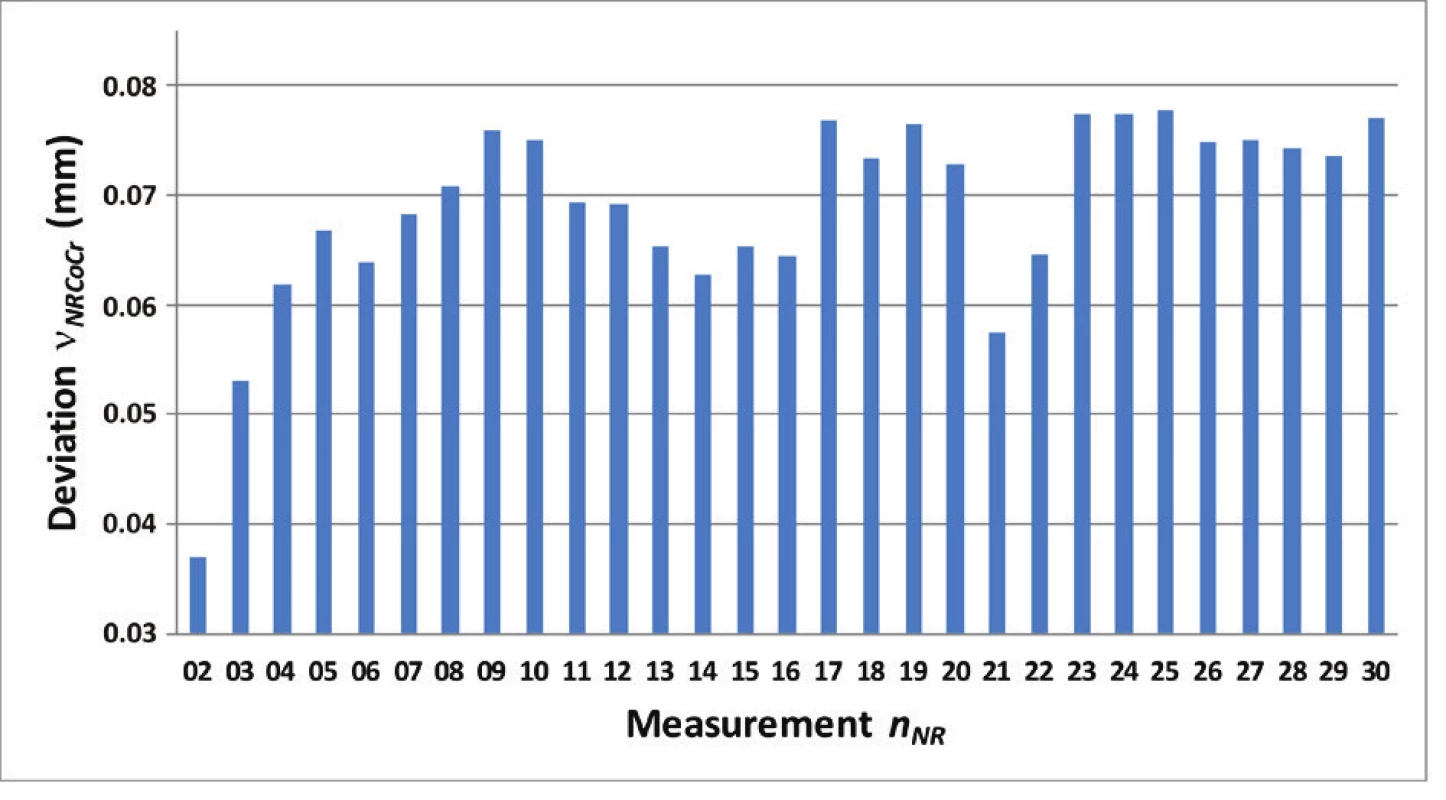

On the basis of the obtained results for crowns made by SLM technology from the metal powder CoCr it can be stated that in the case of analysis the repeatability without removal of the scanned sample no trend is visible between the scans (Fig. 3) and for the set coverage the average deviation is on the level of nNRCoCr=69 µm. For selected titanium sample the maximum deviation nNRTi64 is on the level of 70 µm.

3. Deviations with repeatability without removing of the sample for CoCr.

With respect to the fact that the individual scans were not compared with one another in the software, the assumption is that the deviations are mainly given by mistakes of the scanner (an error in scanning, of setting the coordinate systems of the model). In this case the best coverage is expected because the influences affecting the results of measuring were minimized.In the case of analysis of repeatability with removal of scanned crowns, the deviation for 95% coverage is for CoCr (nRCoCr) on the level of 27 µm. For Ti64 crowns the repeatability with removal (nRTi64) coverage is on the level of 10 µm. In this the influence of taking away the samples should be removed by the software balancing, but at the same time the impact of the software balancing of the monitored and nominal geometry considered.

From a comparison of the obtained data it follows that the deviation in the case of repeatability without taking away the sample is approximately 3-times the deviation of scanning with removal of the crowns. Because the same sample is involved, the assumption is that this difference is caused by the coordinate system of the sample created when scanning. The scans were not in the case of taking the samples away mutually compared and imprecise generation of a coordinate system may then lead to unreal deviations.

This assumption is also supported by the fact that the variation range with the repeatability with removal for CoCr (VRRCoCr) is 12 µm and for titanium 6.5 µm, and thus it is possible to state that the scanner has a high repeatability of sensing. The result also contains an error caused by the software balancing of the scans. For verification of this theory a set was tested in the presence of distant values with the Dixon test, and their presence was not confirmed. On the basis of the abovementioned, it can be stated that the repeatability of the scanning for CoCr is on a level of approximately RRCoCr = 27 µm and for titanium RRTi64 = 10 µm.

This error should be accounted for in the following analysis as with an error on the level of a systematic error. On the basis of the standard deviation sx and the number of measurements n, it is possible to calculate the standard uncertainty of type A uA for the given measurement

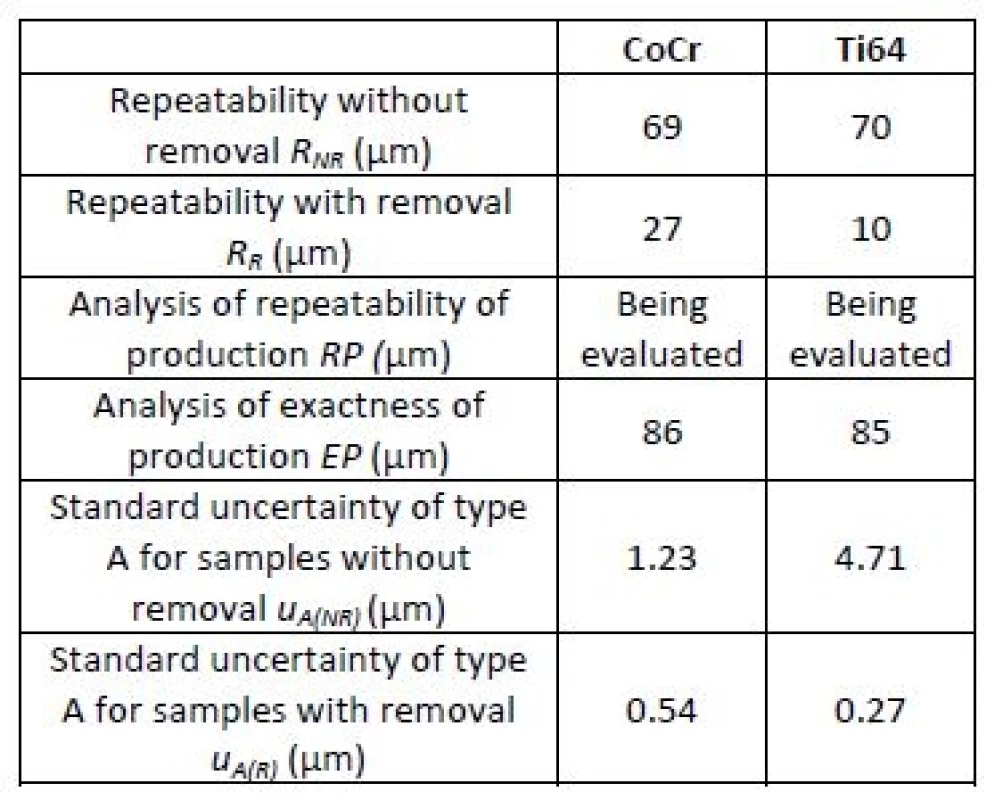

For crowns with removal the material CoCr this is uA(NR)CoCr=0.54 µm and for Ti64 uA(NR)Ti64=0.27 µm. For samples without removal the values of uncertainty type A are in Table 2.

2. Deviations for 95% coverage of the surface in comparison with the reference.

In the case of analysis of repeatability of production, the scans of all evaluated samples are compared in regard to reference geometry (one of the scans). The result is the following of repeatability of the production process. In this case it applies that the better the coverage, the better stability and repeatability of the production process (exactness of production). The measuring is currently being analysed.

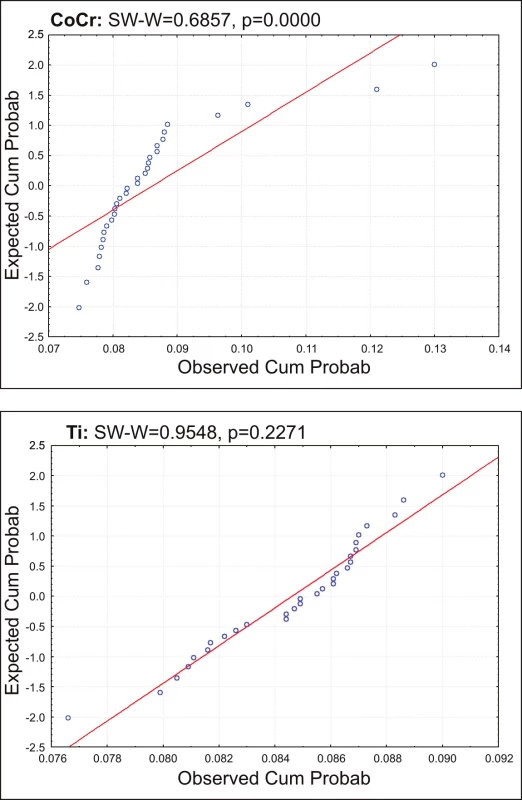

A normality test was conducted for determining whether it is possible to compare data obtained for Ti64 and CoCr (Fig. 4).

4. Test of normality for CoCr and Ti64.

The last analysis is the exactness of production. In this case all scans were compared to the reference geometry used for 3D printing of the *stl model. The largest deviations are expected with respect to the reference in this point. Unlike from precision (achieving of the same result) this analysis gives the exactness of production. The average deviation for the CoCr material EPCoCr is on the level of 86 µm and for Ti64 EPTi64 is on the level of 85 µm.

The results between materials are comparable, the difference is 1 µm.

From the results it follows (Table 2) that the exactness of production for the material CoCr and Ti64 is the same, and production from Ti64 has a better repeatability.

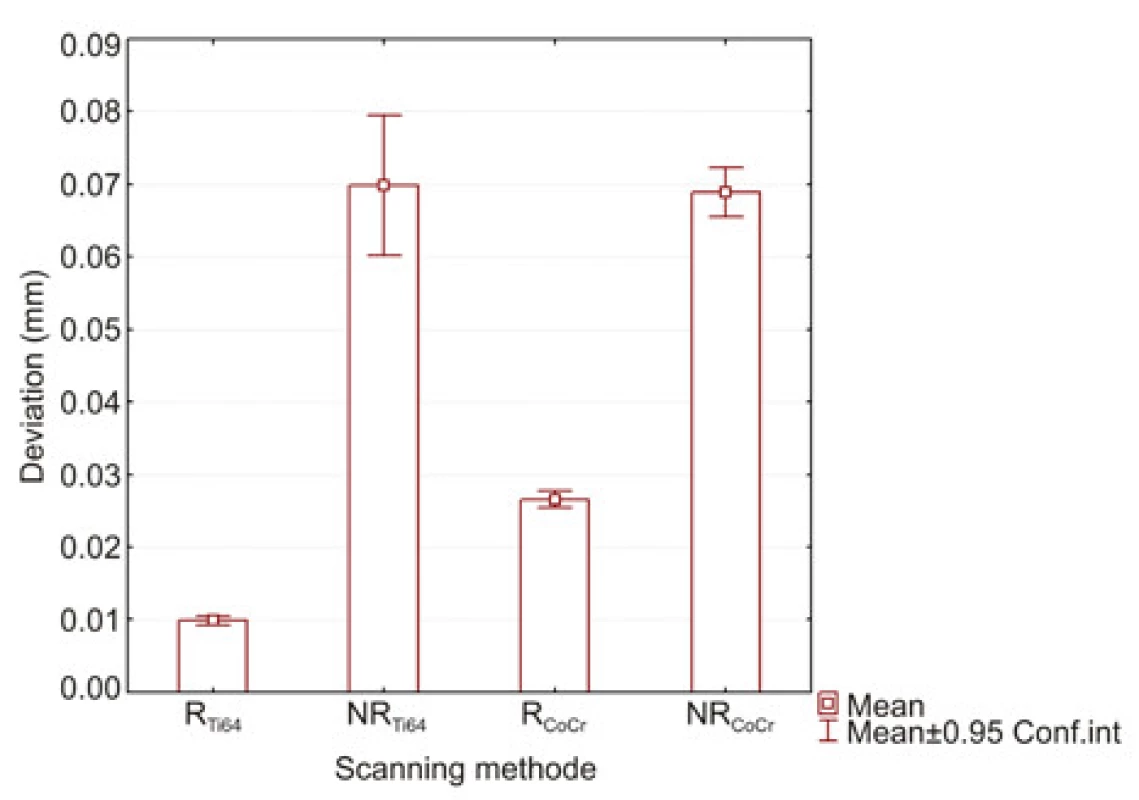

Obtained data are graphically presented in Fig. 5. Differences are observable and statistical significance was evaluated by Mann-Whitney U Test (Wilcoxon rank sum test).

5. Bar graph with a confidence interval for both materials and with a without removal of the scanned crowns.

Hypothesis 1: There is no statistically significant difference between Ti and CoCr alloys in both groups, with and without removal of scanned crowns;

H01a: mRTi64 = mRCoCr and H01b: mNRTi64 = mNRCoCr.Hypothesis 2: There is no statistically significant difference between both groups, with and without removal of scanned samples and for both materials Ti64 and CoCr alloys; H02a: mRTi64 = mRCoCr and H02b: mNRTi64 = mNRCoCr.

Result of Mann-Whitney tests for hypothesis H01a is the following: the Z-Score is -6.53154 and the p-value is <0.00001. The result is significant at p < 0.05. On the level of significance of 0.05 the null hypothesis H01a, was rejected, thus, there is statistically significant difference between products from materials with removal of scanned crowns at the scanning process.

Result of Mann-Whitney test for hypothesis H01b is the following: the Z-Score is 1.63289 and the p-value is 0.1031. The result is not significant at p < 0.05 level. On the level of significance of 0.05 the null hypothesis H01b was accepted; thus, there is not statistically significant difference between products from both materials for the group without removal of scanned crowns at the scanning process. Consequently, therefore is possible to state, that crowns made of Ti64 made with SLM technology have comparable precision as crowns made from the CoCr material using the same technology.

Result of Mann-Whitney test for hypothesis H02a is the following: the Z-Score is -6.53154 and the p-value is < 0.00001. The result is significant at p < 0.05. Result of Mann-Whitney test for hypothesis H02b is the following: the Z-Score is -6.53154 and the p-value is < 0.00001. The result is significant at p < 0.05. On the level of significance of 0.05 the null hypothesis H02a and H02b were rejected, thus, there is statistically significant difference between crowns made of both materials; with and without removal of scanned crowns at the scanning process.

Conclusion

From the results it follows that the scanner has sufficient repeatability and acceptable precision for scanning dental products made with additive manufacturing technology from Ti64 and CoCr. A condition of scanning is dimming the surface of the scanned product. Statistical processing of data confirmed that the scanner provides stable results (scanning is repeatable) and there is no statistically significant difference between crowns made from Ti64 and CoCr. Alloy of titanium thus has, aside from better biocompatibility and weight, also comparable precision after production with CoCr using SLM technology.

Selective laser melting is the one of the most popular AM technology used for dental replacements. For manufacturing are used CoCr alloys and titanium alloys. The repeatability of the scanning for CoCr is on a level of approximately RRCoCr = 27 µm with SD 2.6 µm and for titanium RRTi64 = 10 µm with SD 0.6 µm. Jeon et al. [43] compares repeatability of blue light scanner and white light scanner from Medit. In study was used three abutment tooth types (canine - C, premolar - PM, molar - M). The mean of discrepancies is for C = 5.8 µm, PM = 5.9 µm, M=8.6 µm and the SD of discrepancies is for C=15.9 µm, PM=23.2 µm, M = 14.6 µm pre α = 0.05. The study uses for calculation mean values of discrepancies between scan and nominal surface, our study uses maximum discrepancy for 95% coverage of the surface. From this reason is their mean lower and standard deviation higher than in our study.

Acknowledgement

This article was created within the project 064TUKE-4/2016 Experimental and Calculated Biomechanical Testing of Implantable Medical Devices and its implementation into the educational process and the project (APVV – 14 – 0294) Production and Testing of Made-to-Measure Replacements of Hard Tissues from the Hydroxyapatite (HA) Technology 3D Printing. The work was supported by research grant No. ITMS 26220220185 of the project: Medical University Science Park in Kosice (MediPark) and Medical University Science Park in Kosice, phase II.: ITMS2014+: 313011D103.

Ing. Viktória Rajťúková, PhD.

Department of Biomedical Engineering and Measurement

Mechanical Engineering Faculty

Technical University in Košice

Letná 9, 042 00 Košice, Slovak Republic

E-mail: viktoria.rajtukova@tuke.sk

Telephone: +421 055 602 2651

Sources

- Kalachev, Y., Ralev, R., Jordanov, P.: Finite element tension analysis of the supporting tissues of a maxillary canine. Folia Medica (Plovdiv). 2001; 43(1-2): 105–108.

- Kalachev, Y.: Analysis of stresses in hard dental tissues generated by clinical application of retentive root canal posts. Folia Medica (Plovdiv). 2004; 46(4): 42–46.

- Kato, A., Ohno, N.: Construction of three-dimensional tooth model by micro-computed tomography and application for data sharing. Clin Oral Investig. 2008 May; 13(1): 43–46.

- Kincade, K.: 3D visualization makes learning dental anatomy a snap. Last Updated kk 4/29/2013.

- Strietzel, R.: Selective Laser Melting in Dentistry. Informatics in Oral Medicine: Advanced Techniques in Clinical and Diagnostic Technologies. 2010; 111–125.

- Torabi, K., Farjood, E., Hamedani, S.: Rapid prototyping technologies and their applications in prosthodontics, a review of literature, J Dent Shiraz MedSci, 16 (2015), pp. 1–9.

- van Noort, R.: The future of dental devices is digital, Dental Materials, Volume 28, Issue 1, 2012, Pages 3–12, ISSN 0109-5641, http://dx.doi.org/10.1016/j.dental.2011.10.014.

- Ohkubo, Ch., et al.: Effect of implant support on distal-extension removable partial dentures: in vivo assessment. International Journal of Oral & Maxillofacial Implants 23.6 (2008). Witkowski, S.: (CAD-)/CAM in der Zahntechnik: Buyer’s Guide 2003. Zahntech Mag. 2002; 6 : 696–709.

- Dikova, Ts., et al.: Modern trends in the development of the technologies for production of dental constructions, Journal of IMAB–Annual Proceeding Scientific Papers 21.4 (2015): 974–981.

- Jeng, J. Y., Chang, K. Y., Dong, D. R., Shih, H. S.: Tooth crown fabrication using reverse engineering technology and model maker rapid prototyping system. Rapid Prototyp J, 2000, 6(2): 136–145.

- Jeng, J. Y., Chen, C. Y., Chen, S., Chen, R.: Application of a micro-CT scan to tooth crown dimensions measurement and CAD model construction for rapid prototyping. J Chin Soc Mech Eng, 2000, 21(3): 321–324.

- Hong, Min-Ho, Bong Ki Min, and Tea-Yub Kwon: Fabricating High-Quality 3D-Printed Alloys for Dental Applications, Applied Sciences 7.7 (2017): 710.

- Lima, J. M., Anami, L., Araujo, R. M., Pavanelli, C. A.: Removable partial dentures: use of rapid prototyping, J Prosthodont, 23 (2014), pp. 588–591.

- Williams, R. J., Bibb, R., Eggbeer, D., et al: Use of CAD/CAM technology to fabricate a removable partial denture framework. J Prosthet Dent 2006; 96 : 96–99.

- Koutsoukis, T., et al.: Selective Laser Melting Technique of Co‐Cr Dental Alloys: A Review of Structure and Properties and Comparative Analysis with Other Available Techniques, Journal of Prosthodontics 24.4 (2015): 303–312.

- Castillo-Oyague, R., Osorio, R., Osorio, E., et al: The effect of surface treatments on the microroughness of laser-sintered and vacuum-cast base metal alloys for dental prosthetic frame-works. Microsc Res Tech 2012; 75 : 1206–1212.

- Ucar, Y., Akova, T., Akyil, M. S., et al: Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent 2009; 102 : 253–259.

- Castillo-de-Oyague, R., Sanchez-Turrion, A., Lopez-Lozano, J. F., et al: Vertical misfit of laser-sintered and vacuum-cast implant-supported crown copings luted with definitive and temporary luting agents. Med Oral Patol Oral Cir Bucal 2012; 17: e610–617.

- Castillo-Oyague, R., Lynch, C. D., Turrion, A. S., et al: Misfit and microleakage of implant-supported crown copings obtained by laser sintering and casting techniques, luted with glass-ionomer, resin cements and acrylic/urethane-based agents. J Dent2013; 41 : 90–96.

- Oyague, R. C., Sanchez-Turrion, A, Lopez-Lozano, J. F., et al: Evaluation of fit of cement-retained implant-supported 3-unit structures fabricated with direct metal laser sintering and vacuum casting techniques. Odontology 2012; 100 : 249–253.

- Tara, M. A, Eschbach, S., Bohlsen, F., et al: Clinical outcome of metal-ceramic crowns fabricated with laser-sintering technology. Int J Prosthodont 2011; 24 : 46–48.

- Xiang, N., Xin, X. Z., Chen, J., et al: Metal-ceramic bond strength of Co-Cr alloy fabricated by selective laser melting. J Dent 2012; 40 : 453–457.

- Xin, X. Z., Chen, J., Xiang, N., et al: Surface properties and corrosion behavior of Co-Cr alloy fabricated with selective laser melting technique. Cell Biochem Biophys 2013; 67 : 983–990.

- Ortorp, A., Jonsson, D., Mouhsen, A., et al: The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: a comparative in vitro study. Dent Mater 2011; 27 : 356–363.

- Hama Suleiman, S., Vult von Steyern, P.: Fracture strength of porcelain fused to metal crowns made of cast, milled or laser-sintered cobalt-chromium. Acta Odontol Scand 2013; 71 : 1280–1289.

- Takaichi, A., Suyalatu, Nakamoto, T., et al: Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications. J Mech Behav Biomed Mater 2013; 21 : 67–76.

- Craig, R. G., Powers, J. M., Wataha, J. C.: Dental Materials: Properties and Manipulation (7th ed), Mosby, Missouri (2000), pp. 229–231.

- Choi, Y. J., Koak, J. Y., Heo, S. J., Kim, S. K., Ahn, J. S., Park, D. S.: Comparison of the mechanical properties and microstructures of fractured surface for Co-Cr alloy fabricated by conventional cast, 3-D printing laser-sintered and CAD/CAM milled techniques. J Korean Acad Prosthodont. 2014 Apr; 52(2): 67–73.

- Powers, J. M., Sakaguchi, R. L.: Craig’s Restorative Dental Materials (12th ed), Mosby, Missouri (2006).

- Wataha, J. C.: Alloys for prosthodontic restorations, Journal of Prosthetic Dentistry, 87 (2002), pp. 351–363.

- Ameer, M. A., Khamis, E., Al-Motlaq, M.: Electrochemical behaviour of recasting Ni-Cr and Co-Cr non-precious dental alloys, Corros Sci, 46 (2004), pp. 2825–2836.

- Anusavice, K. J., Shen, C., Rawls, H. R.: Phillips’ science of dental materials (12th ed.), Saunders/Elsevier, St Louis (2013), pp. 367–396.

- Viennot, S., Dalard, F., Lissac, M., Grosgogeat, B.: Corrosion resistance of cobalt-chromium and palladium-silver alloys used in fixed prosthetic restorations. Eur J Oral Sci 2005; 113 : 90–95.

- de Vasconcellos, L. G., Buso, L., Lombardo, G. H., Souza, R. O., Nogueira, L. Jr., Bottino, M. A., Ozcan, M.: Opaque layer firing temperature and aging effect on the flexural strength of ceramic fused to cobalt-chromium alloy. J Prosthodont 2010; 19 : 471–477.

- Markhoff, J.; Krogull, M.; Schulze, C.; Rotsch, C.; Hunger, S.; Bader, R.: Biocompatibility and inflammatory potential of titanium alloys cultivated with human osteoblasts, fibroblasts and macrophages. Materials 2017, 10, 52.

- Witkowski, S., Komine, F., Gerds, T.: Marginal accuracy of titanium copings fabricated by casting and CAD/CAM techniques, The Journal of Prosthetic Dentistry, Volume 96, Issue 1, 2006, Pages 47–52, ISSN 0022-3913.

- Tschernitschek, H., Borchers, L., Guertsen, W.: Nonalloyed titanium as a bioinert metal-a review, Quintessence Int, 36 (2005), pp. 523–530.

- Süleyman Hakan Tuna, Nuran Özçiçek Pekmez, Işın Kürkçüoğlu: Corrosion resistance assessment of Co-Cr alloy frameworks fabricated by CAD/CAM milling, laser sintering, and casting methods, The Journal of Prosthetic Dentistry, Volume 114, Issue 5, 2015, Pages 725–734, ISSN 0022-3913.

- Siegbert Witkowski, Futoshi Komine, Thomas Gerds: Marginal accuracy of titanium copings fabricated by casting and CAD/CAM techniques, The Journal of Prosthetic Dentistry, Volume 96, Issue 1, 2006, Pages 47–52, ISSN 0022-3913.

- Jemt, T., Linden, B.: Fixed implant-supported prostheses with welded titanium frame works, Int J Periodontal Restor Dent, 12 (1992), pp. 176–183.

- Jin, L., Li, P. Z., Zhou, H. B., Zhang, W., Zhou, G. D., Wang, C.: Improving thermal insulation of TC4 using YSZ-based coating and SiO2 aerogel, Prog. Nat. Sci. Mater. Int., 25 (2015), pp. 141–146.

- Wu, M., Tinschert, J., Augthun, M., Wagner, I., Schädlich-Stubenrauch, J., Sahm, P. R., Spiekermann, H.: Application of laser measuring, numerical simulation and rapid prototyping to titanium dental castings, Dental Materials, Volume 17, Issue 2, 2001, Pages 102–108, ISSN 0109-5641.

- Jin-Hun Jeon, Byeong-Yeol Choi, Chong-Myeong Kim, Ji-Hwan Kim, Hae-Young Kim, Woong-Chul Kim: Three-dimensional evaluation of the repeatability of scanned conventional impressions of prepared teeth generated with white - and blue-light scanners, The Journal of Prosthetic Dentistry, Volume 114, Issue 4, 2015, P. 549–553, ISSN 0022-3913.

Labels

Biomedicine

Article was published inThe Clinician and Technology Journal

2018 Issue 1-

All articles in this issue

- Median method for determining cortical brain activity in a near infrared spectroscopy image

- Patient´s respiratory curve synchronization by visual feedback application

- A comparsion of the quality of dental crowns from TI-6AL-4V and cocr alloys made with SLM technology

- Dimensionality reduction methods for biomedical data

- Agcu bimetallic nanoparticles modified by polyvinyl alcohol - the cells viability study in vitro

- The Clinician and Technology Journal

- Journal archive

- Current issue

- Online only

- About the journal

Most read in this issue- Median method for determining cortical brain activity in a near infrared spectroscopy image

- A comparsion of the quality of dental crowns from TI-6AL-4V and cocr alloys made with SLM technology

- Dimensionality reduction methods for biomedical data

- Patient´s respiratory curve synchronization by visual feedback application

Login#ADS_BOTTOM_SCRIPTS#Forgotten passwordEnter the email address that you registered with. We will send you instructions on how to set a new password.

- Career