-

Medical journals

- Career

THE MARGINAL AND INTERNAL FIT OF COCR ALLOY SINGLE CROWNS WITH PREPARATION DESIGNS INCLUDING AUXILIARY FEATURES; CAD/CAM VERSUS CONVENTIONAL TECHNIQUE

Authors: K. Walczak; D. Friedrichs; H. Meissner; K. Boening

Authors‘ workplace: Oddělení protetické stomatologie, Lékařská fakulta Carla Gustava Caruse, Technická univerzita, Drážďany, SRN

Published in: Česká stomatologie / Praktické zubní lékařství, ročník 120, 2020, 3, s. 78-85

Category: Original articles

Overview

Objectives: Evaluation of the influence of complex tooth preparation designs with incorporated auxiliary features on the marginal and internal fit of computer-aided design (CAD), and either additive (SLM) or subtractive (milling) computer-aided manufactured (CAM) and conventionally cast CoCr alloy single crowns (SC).

Material and methods: Artificial teeth were prepared with four different preparation designs: chamfer standard preparation (SP, as control), chamfer preparation with occlusal isthmus (OP), chamfer preparation with proximal boxes (BP) and chamfer preparation with buccal/lingual grooves (GP). Five crowns were made from each preparation design by cast technique (CT), milling technique (MT) and selective laser melting (SLM). The marginal and internal fit of the crowns was analysed by the silicone replica technique. The internal fit was evaluated by measuring axial, occlusal and gaps within auxiliary features. Mean and maximal gap widths values were evaluated. The Kruskal-Wallis test and U-test (Bonferroni adjusted) were used for the statistical analysis (p ≤ 0.05).

Results: For SP and OP, the marginal fit was similar between CT and MT as well as between CT and SLM. For SP and OP, the occlusal gaps were the lowest for CT and significantly different to SLM. For BP and GP, the marginal fit was statistically significantly better for CT than MT. The internal fit for BP and GP was best for CT.

Conclusions: Within all preparation designs with auxiliary features, only the CT achieved clinically acceptable values for both marginal and internal fit. Tested CAD/CAM systems and their software versions need further improvement to implement preparation designs with auxiliary features.

Keywords:

marginal fit – internal fit – CAD/CAM – milling – SLM – sintering – casting technique

INTRODUCTION

Sufficient resistance and retention in tooth preparation design are crucial factors to avoid dislodgements of single crowns (SC) or FDPs. Slightly tapered axial walls, sufficient crown length, and surface area are primary factors to achieve resistance and retention [1]. If short clinical crowns or tipped abutment teeth do not allow appropriate crown retention auxiliary preparation measures such as groves, proximal boxes or pinholes are recommended to enhance crown retention [1–4].

In past years CAD/CAM processing has become popular in dentistry [5–9]. The digitized manufacturing process shall reduce time, costs and open the diversity of materials in dentistry [5, 7]. Traditional lost-wax casting techniques are time-consuming and technique sensitive [10]. Milling became a popular method when manufacturing dental ceramic restorations and in the meanwhile, it can be considered an almost universal technique to process a wide range of dental materials [11, 12]. Irrespective of its high versatility milling is a subtractive machining method and thus associated with some inherent disadvantages such as waste of material, microstructural differences in material blanks, wear of tools and a spatial resolution that is limited by cutting tool size especially when manufacturing complex shapes or designs [6, 7, 10, 12, 13]. Contrary, selective laser melting (SLM) is an additive manufacturing method to process alloys within the digital workflow [10]. SLM is described as a fast method to produce complex designs not limited by the shape or size of a milling tool [10, 13]. Because of its high capability to save costs, SLM is being intensively investigated and considered a true alternative to dental casting by some authors [13–16].

CAD/CAM technologies are in the focus of the dental community [13–16]. However, there is still inconsistency in results and recommendations. Especially, in the case of recommendation of CAD/CAM technologies as capable to replace conventional casting technique for all indication fields [9].

Concerning clinically acceptable marginal and internal fit of crowns literature statements are inconclusive [15, 17–23]. Theoretical recommendations for optimal cement film thickness are between 25 µm and 50 µm, defined as minimal grain size of zinc phosphate cement [17]. Nevertheless, these theoretical recommendations for cement film thickness are difficult to achieve [17]. McLean and Fraunhofer judged maximal marginal gaps up to 120 µm as clinical acceptable, other authors allow values up to 200 µm [18, 19]. Regarding internal fit mean discrepancies up to 100 µm are described as clinically acceptable [17, 20, 21]. Nevertheless, other studies described axial gaps up to 160 µm and occlusal gaps up to 350 µm as acceptable [15, 22, 24].

Numerous studies evaluated the suitability of SLM, milling and casting techniques for metal-based crowns and FDPs [7, 15, 19, 24–35]. The authors concluded that the fit of SLM and/or milled restorations was comparable to cast restorations and thus stated that current CAD/CAM technology can be considered a feasible alternative to traditional casting technique [14, 15, 19, 25,27, 30–32, 34]. However, aforementioned studies mainly focused on standard crown preparation designs [7, 15, 19, 22, 24–35]. Although the application of CAD/CAM technology in dentistry has increased substantially [5–7], there is little information to what extent CAD/CAM systems are capable to manufacture complex intaglio crown surfaces that correspond to tooth preparation designs including auxiliary retentive features as boxes or groves. Such data are of value in the assessment of digital fabrication methods as a fully reliable substitute for the traditional casting technique.

The aim of the present study was to evaluate the fit of milled, SLM manufactured and cast single crowns with tooth preparation designs that comprise occlusal isthmus, proximal boxes or grooves to improve crown resistance and retention. The following null hypotheses were stated:

- The marginal fit of milled or SLM SC is similar to cast SC in all preparation designs tested.

- The internal fit axial, occlusal and within auxiliary features for milled or SLM SC is similar to cast SC in all preparation designs tested.

MATERIAL AND METHODS

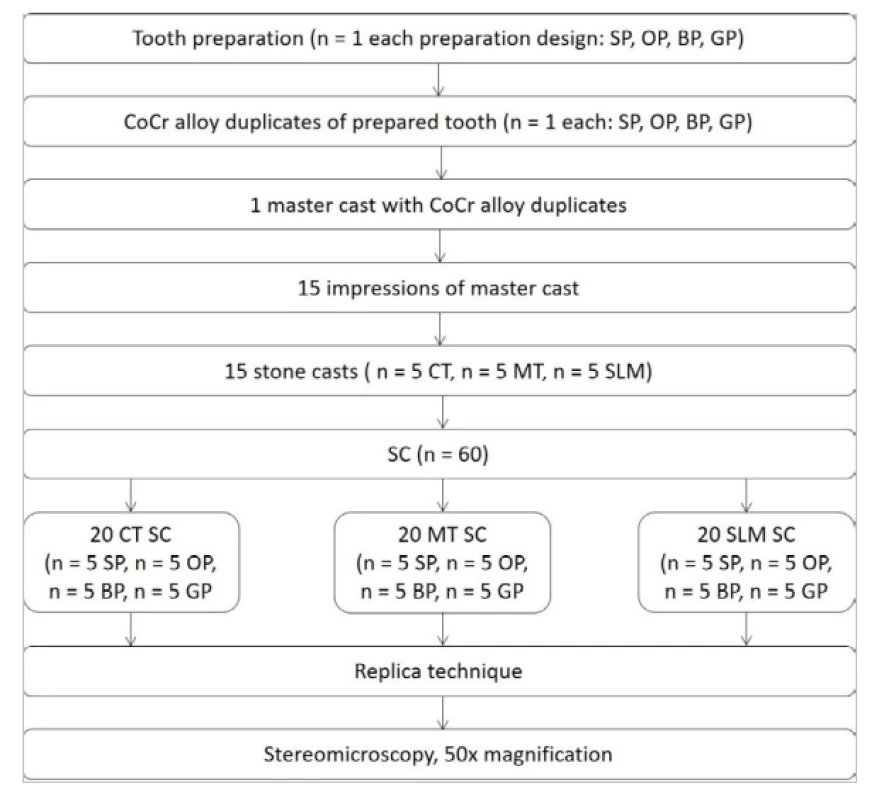

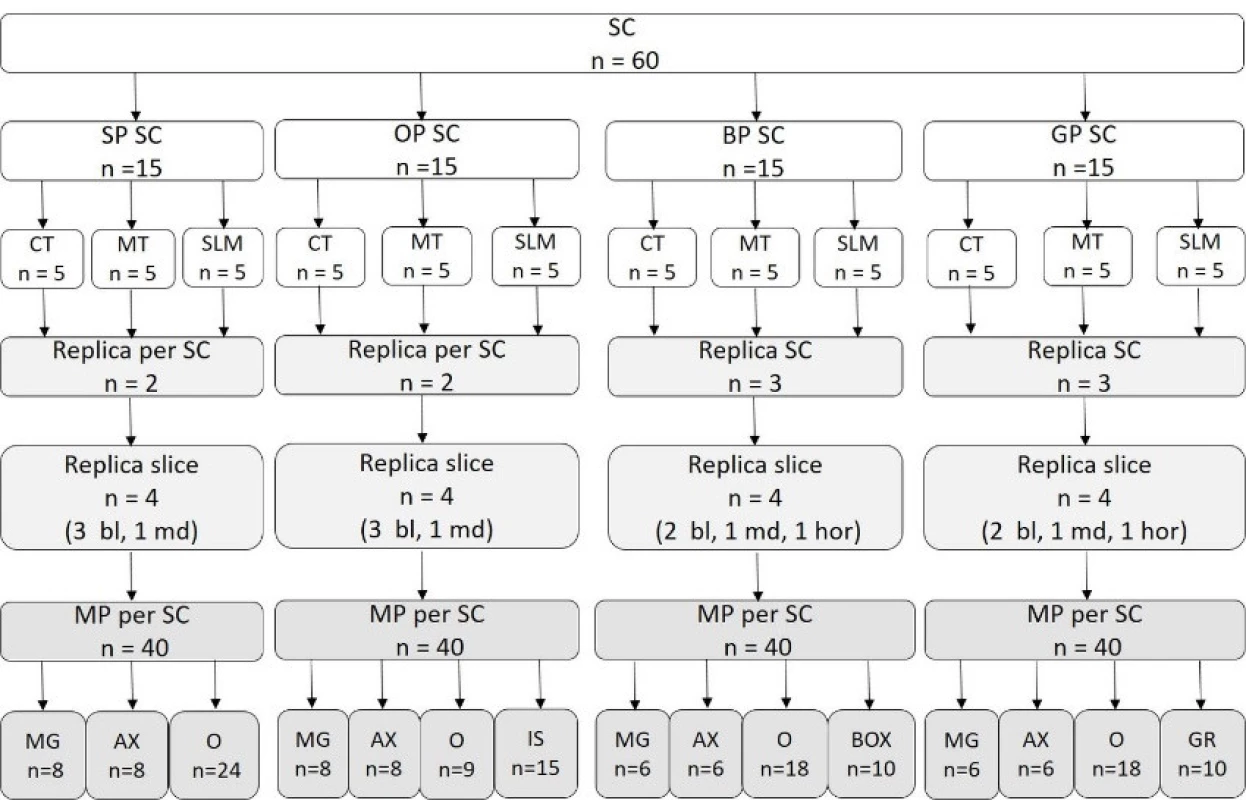

The study was conducted in 2013–2015 according to the flowchart shown in Figure 1. Four artificial mandibular second left molars (Frasaco model tooth, 37 A-3ZE, Frasaco GmbH) were prepared by one operator as follows: standard chamfer preparation (SP, control), chamfer preparation with an occlusal isthmus (OP), chamfer preparation with additional proximal boxes (BP) and chamfer preparation with buccal and lingual grooves (GP), one preparation design each. The auxiliary features were prepared to improve resistance and retention. All preparation designs had a chamfer finish line, a total convergence angle of 12°, a circular reduction of 1 mm and an occlusal reduction of 1.5 mm. Conical burs (FG2536040G, Ökodent GmbH) were used for all preparations. Tooth preparation was standardized by the use of a parallelometer (EWL 990, KaVo Dental GmbH).

1. Study design. Single crowns (SC), standard preparation (SP), preparation with occlusal isthmus (OP), preparation with buccal/lingual grooves (GP), preparation with proximal boxes (BP), cast technique (CT), milling (MT), selective laser melting (SLM)

For further replica technique in each preparation design, one cast CoCr alloy duplicates (die) of the prepared tooth (Wirobond C, Bremer Goldschlägerei Wilh. Herbst GmbH & Co. KG) were made. The four duplicates were embedded in a stone base to prepare master cast. From this master cast, fifteen polyether impressions (Impregum Penta Soft, 3M) were made and poured in stone (CAM-Base, Dentona AG).

These fifteen stone casts were used to produce CoCr alloy SC. Five stone casts were used for cast technique (CT), five for milling technique (MT), and five for selective laser melting (SLM).

Sixty CoCr alloy SC were manufactured as follows: twenty CT (n = 5 for each preparation design), twenty MT (n = 5 for each preparation design) and twenty SLM (n = 5 for each preparation design). The cast crowns were made in the lost-wax technique by one experienced technician in the Department of Prosthetic Dentistry. Subsequently, the stone dies were covered with one layer of die spacer (Durolan, DFS) starting 1 mm above the preparation margin. Wax patterns were formed (THOWAX Cervikalwachs rot, THOWAX Modellierwachs blau, Yeti Dental GmbH), invested and cast (Wirobond C, Bremer Goldschlägerei Wilh. Herbst GmbH & Co. KG) with a casting machine (Nautilus, Bremer Goldschlägerei Wilh. Herbst GmbH & Co. KG). The milled crowns were produced by the Nobel Biocare Scan and Design Service Center (NobelProcera Services, Nobel Biocare,), SLM crowns by BEGO Scan and Design Center (BEGO Medical GmbH). Each company received five stone casts and the complete CAD/CAM process occurred there. Each preparation design five CoCr-based SC were ordered without giving further specific instructions about the scanning and designing parameters. This procedure was chosen to simulate a daily dental practice environment. The Scan and Design Service Center of Nobel Biocare used a virtual cement space of 50 µm to 80 μm ± 5 μm for milled SC (further information’s were not given from the manufacturer). BEGO used an extraoral model scanner (3Shape D 800, 3ShapeA/S, Copenhagen) and CAD software Dental Designer 2013 (3ShapeA/S), the virtual cement space was set at 70 μm. For SLM SC manufacturing Eosin M280 machine (EOS GmbH) was used with the following parameters: the metal layer thickness of 0.03 mm and between 150 to 200 layers. After manufacturing the inner surface of all SC was not manually adjusted for a better fit.

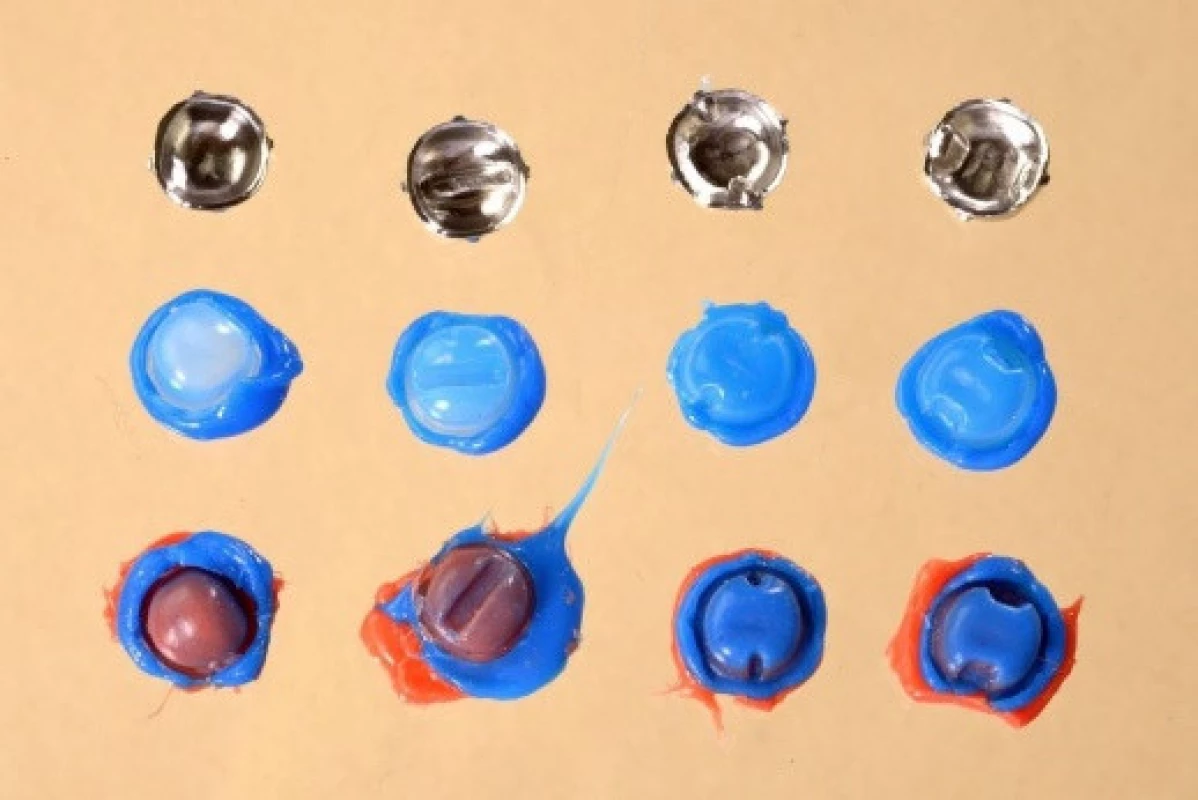

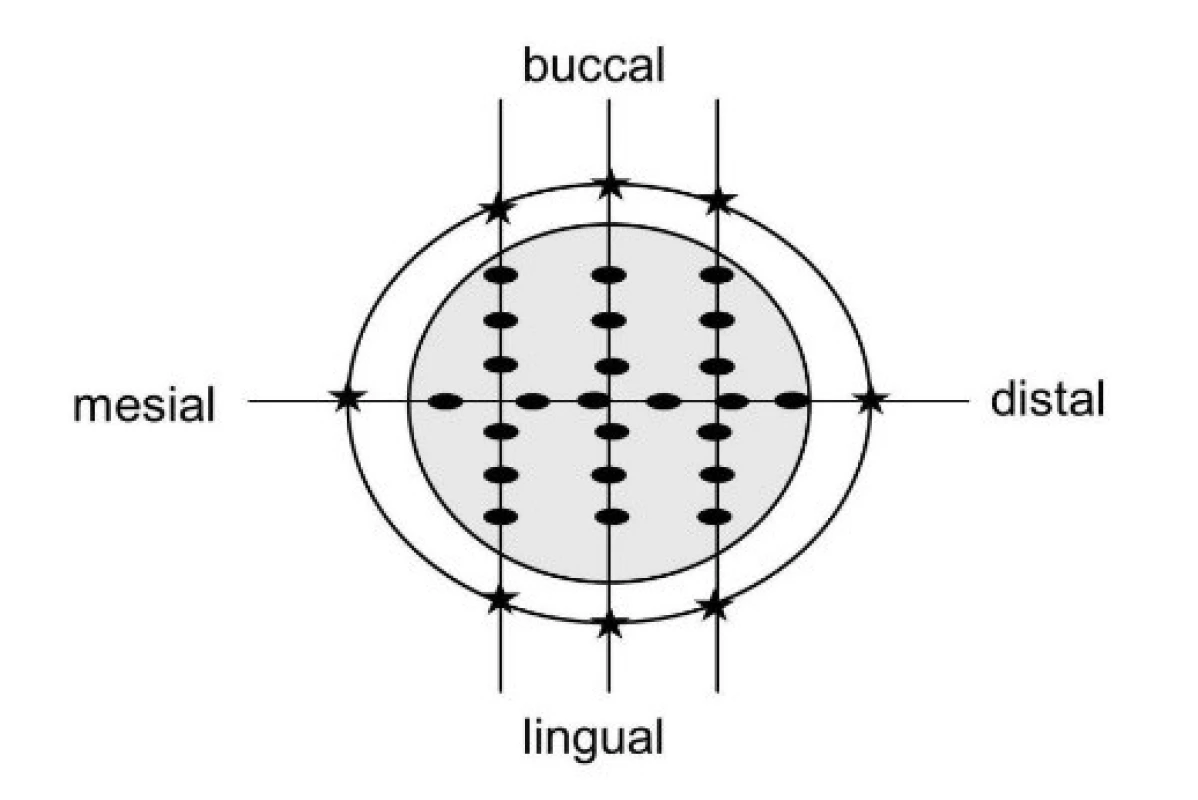

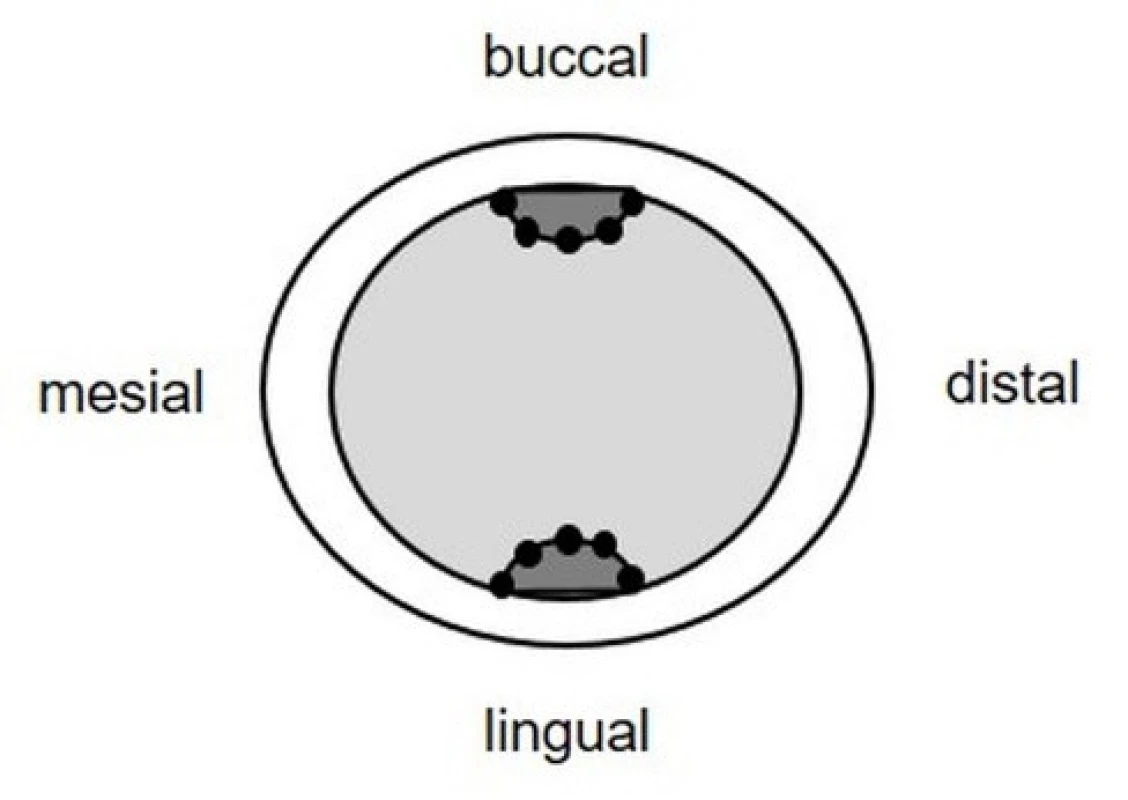

To quantify the marginal and internal fit of the crowns, silicone replicas of the cement gap between alloy tooth duplicate (master cast) and the crown were made by filling the inner crown with silicone impression material (Xantopren L blue, Heraeus Kulzer GmbH) and firmly pressing the crown on the corresponding tooth duplicate by hand. The thin silicone replicas were backfilled with a silicone impression material of different color (Xantopren M mucosa, Heraeus Kulzer GmbH) for mechanical support (Fig. 2). For each SC, two replicas for SP and OP and three replicas for BP and GP were made. The silicone replicas were sectioned in 1.5 mm thick slices with a twin blade cutter. The replicas for SP and OP were sectioned three times in the bucco-lingual direction and one time in the mesio-distal direction (Fig. 3). The replicas for BP and GP were sectioned two times in the bucco-lingual direction and one time in the mesio-distal direction. Additionally, they were sectioned one time horizontally in the middle of the replica. Resulting in four slices per crown for further microscopic evaluation.

2. Milled crowns for tested preparation designs with replicas before sectioning (from left to right: standard preparation (SP), preparation with occlusal isthmus (OP), preparation with buccal/ lingual grooves (GP) and preparation with proximal boxes (BP)

3. Replicas sectioning plan for standard preparation design (SP) and preparation design with occlusal isthmus (OP): in the bucco-lingual direction (3 times) and in the mesio-distal direction (1 time). With measuring points occlusal (dots, 6 points each slice) marginal (stars, 2 points each slice) and axial (not marked, 2 points each slice)

To evaluate the marginal fit the marginal gaps, defined according to Holmes et al. were measured [36]. To assess the internal fit axial gaps, occlusal gaps and gaps within the auxiliary features (proximal boxes, retentive grooves, occlusal isthmus) were evaluated, focusing especially on the fit within auxiliary features. All mentioned gaps were defined as a perpendicular distance from the crown inner surface to the corresponding tooth surface. The gaps, equivalent to film thickness from the silicone replica were measured with a light microscope, 50times magnification (LEICA MZ, LEICA AG) and dhs software (dhs Image Data Base, Version 14, dhs Dietermann & Heuser Solution GmbH).

All measurements were taken at ten predefined points per slice. For each bucco-lingual and mesio-distal slice two measurement points were located on preparation margin, two on the axial wall (1mm above the preparation margin) and six occlusal. For crowns with occlusal isthmus, three of the occlusal measuring points were located in the isthmus in the bucco-lingual slices and six in the mesio-distal slice. The measurement points on the horizontal slice of crowns with proximal boxes or buccal/lingual groves were five per site in each auxiliary feature (Fig. 4). In total, 2,400 measurement points were evaluated by one examiner (Fig. 5). For each crown two values were evaluated from measured data: (1) mean gap width at the margin, axial, occlusal and within the auxiliary feature, (2) maximal gap width at the margin, axial, occlusal and within the auxiliary feature [37].

4. Horizontally cut replica slice. Measuring points (dots) in buccal/lingual grooves and proximal boxes respectively (5 points each)

5. Replica technique design. Single crowns (SC): standard preparation (SP), preparation with occlusal isthmus (OP), preparation with proximal boxes (BP), preparation with buccal/lingual grooves (GP), cast technique (CT), milling technique (MT), selective laser melting (SLM); measuring points (MP): marginal (MG), axial (AX), occlusal (O), in occlusal isthmus (IS), in proximal box (BOX), in buccal/lingual groove (GR); replica slices: bucco-lingual (bl), mesio-distal (md), horizontal (hor)

The Kruskal-Wallis and U-Test (Bonferroni adjusted) were used for the statistical analysis (SPSS Statistics Version 23, IBM Corp). The significance level was set at p ≤ 0.05.

RESULTS

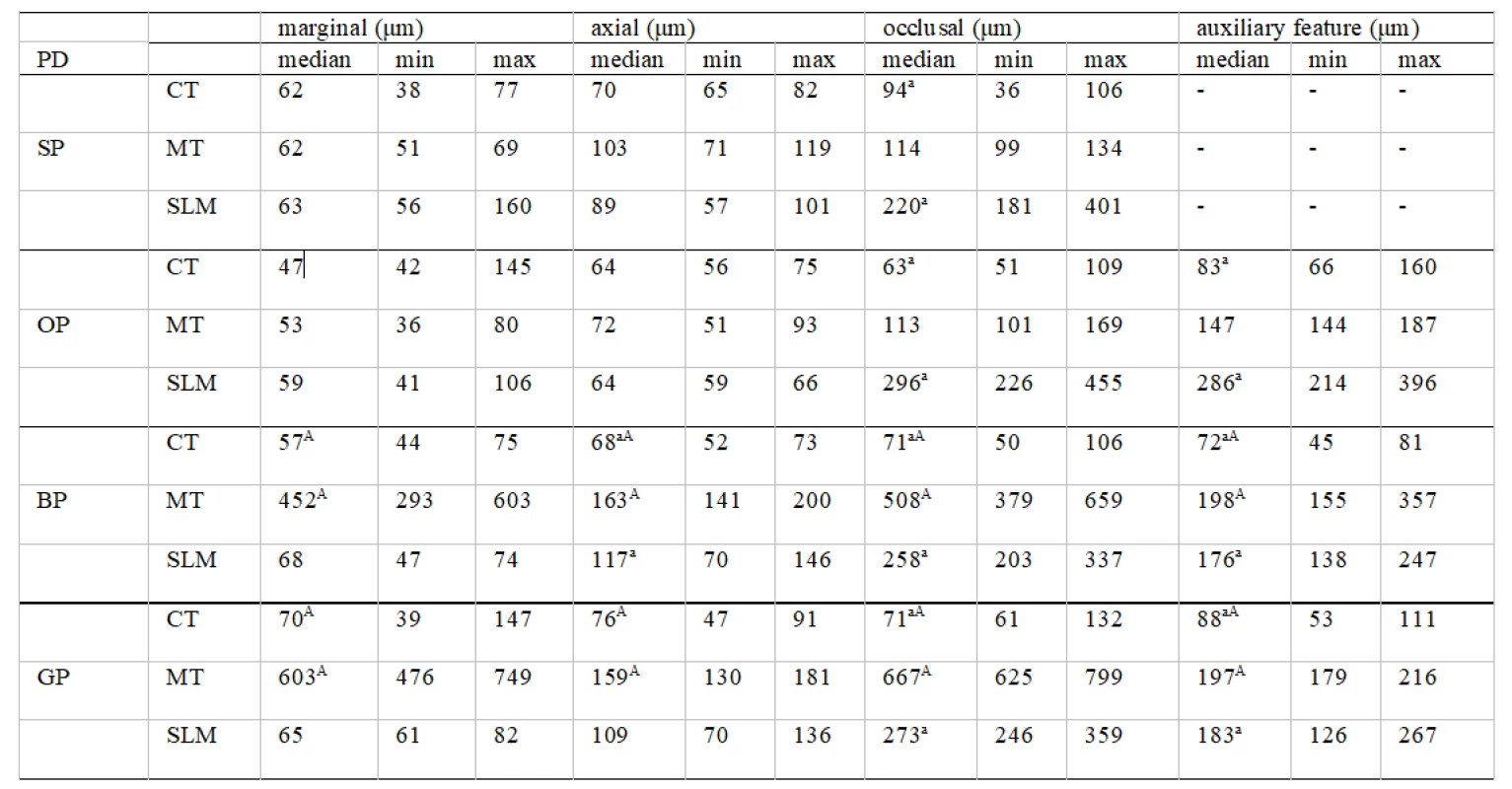

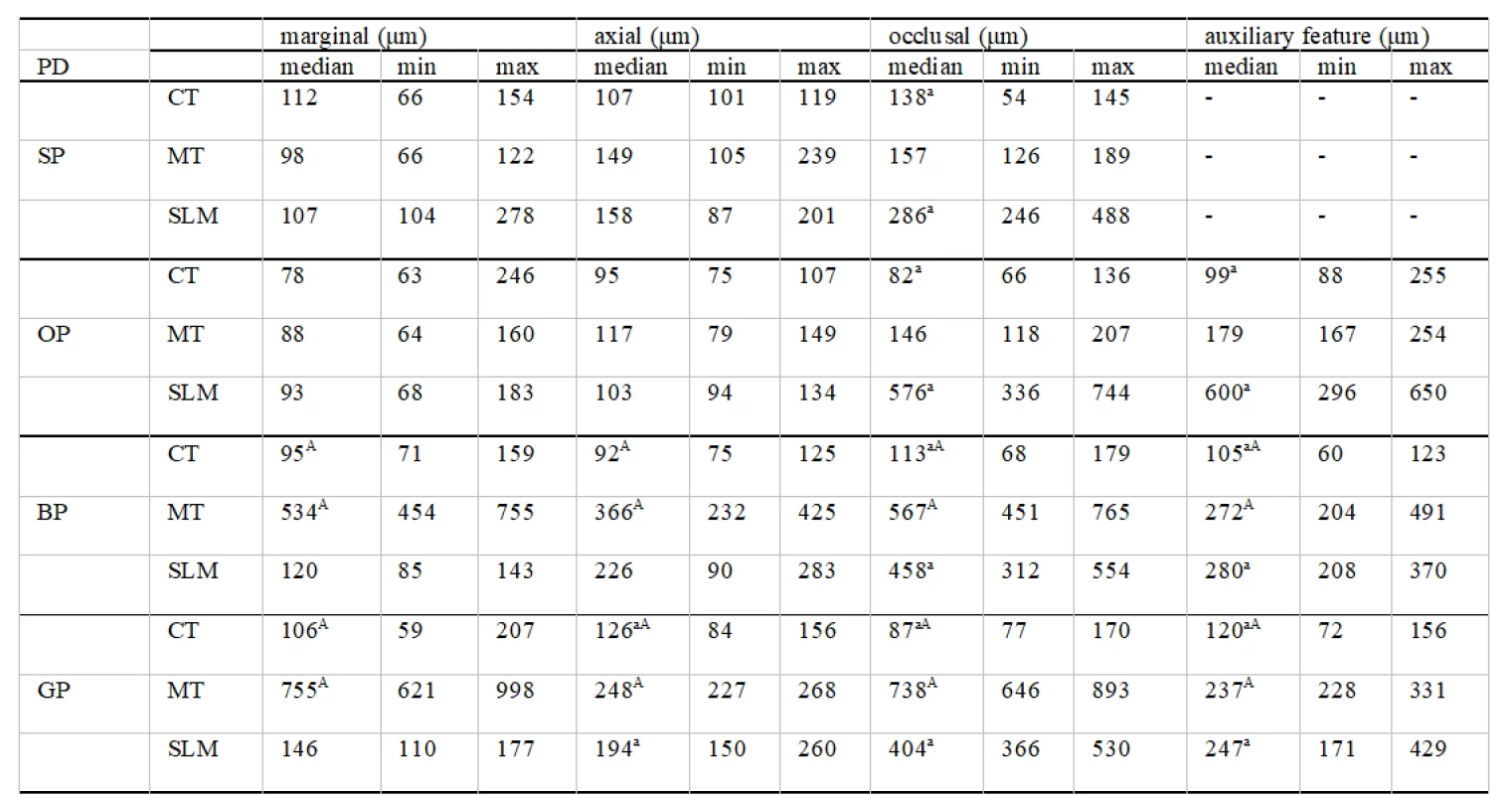

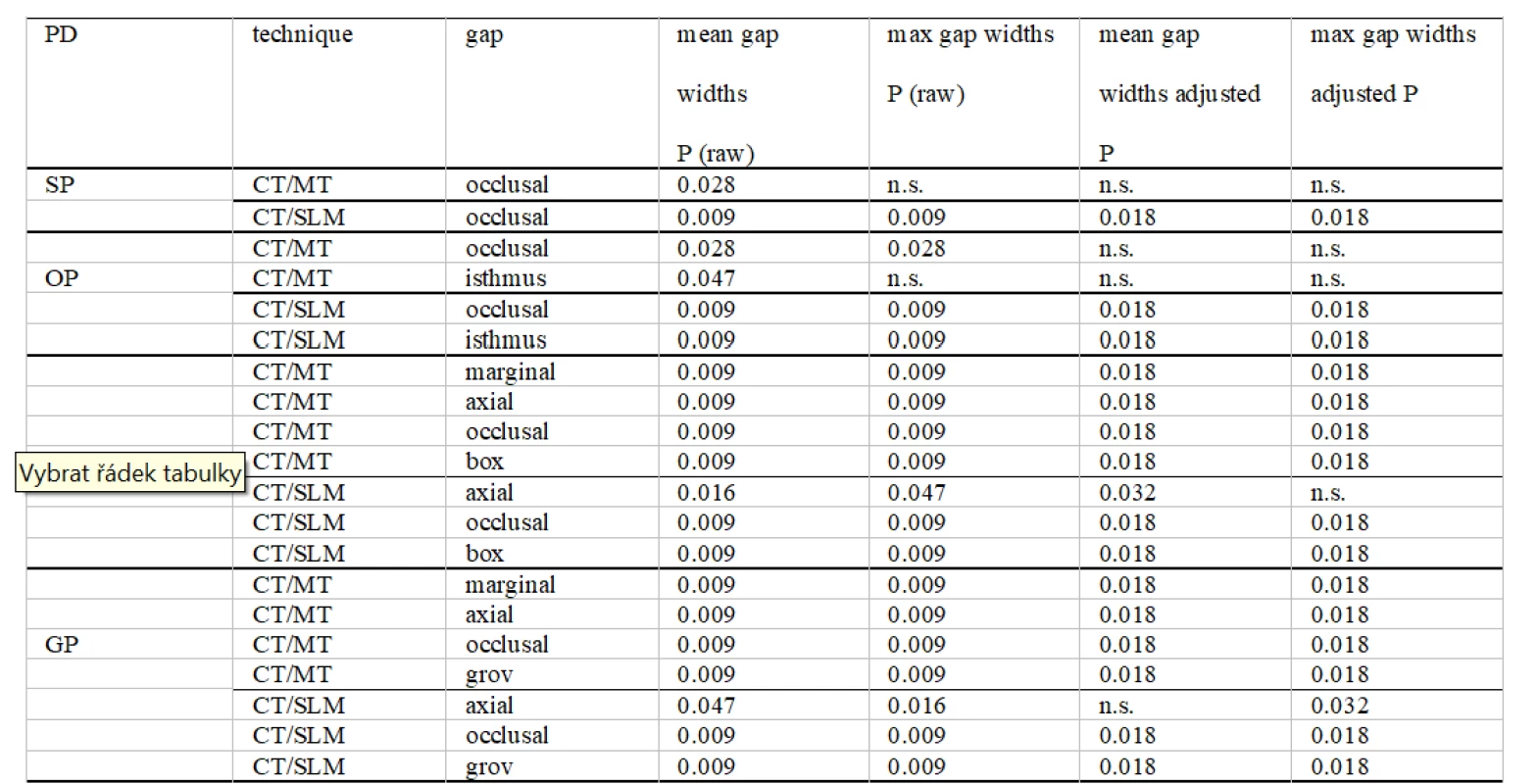

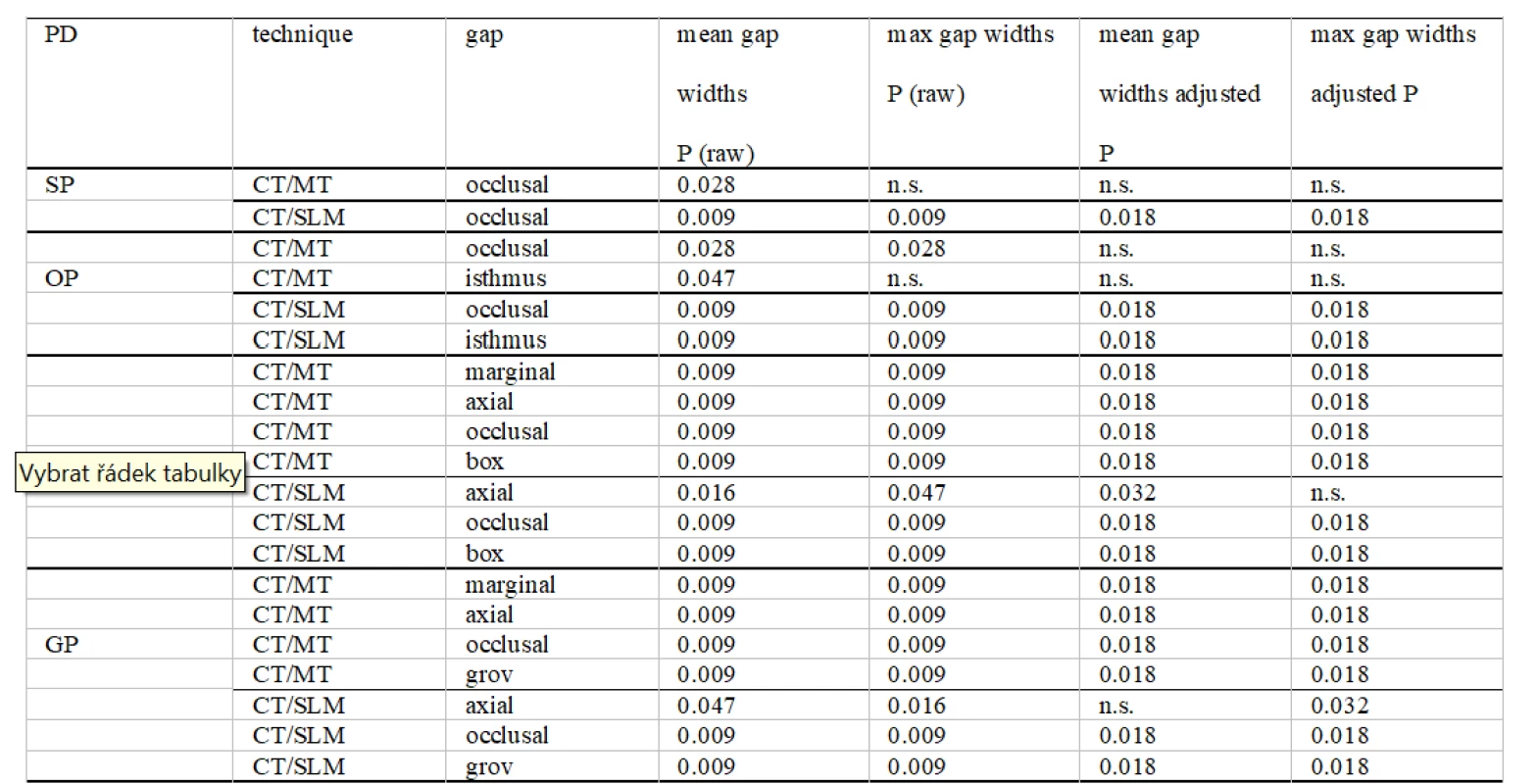

The median and extreme values of mean and maximal gap width are listed in Tables 1 and 2. The data were not distributed normally (Kolmogorov-Smirnov and Shapiro-Wilk test), therefore non-parametric statistical analysis was conducted. The raw and adjusted p values ≤ 0.05 are showed in Table 3.

1. Median and extreme values of mean gap widths (marginal, axial, occlusal, within auxiliary features) for CT, MT and SLM SC for preparations designs (PD): standard (SP), with occlusal isthmus (OP), with boxes (BP) and with groves (GP)

PD preparation design, CT cast technique, MT milling technique, SLM selective laser melting, for each preparation design “a” superscript letter indicate a statistically significant difference between CT and SLM and “A” superscript letter indicate a statistically significant difference between CT and MT (p ≤ 0.05 Bonferroni adjusted) 2. Median and extreme values of maximal gap widths (marginal, axial, occlusal, within auxiliary features) for CT, MT and SLM SC for preparations designs (PD): standard (SP), with occlusal isthmus (OP), with boxes (BP) and with groves (GP)

PD preparation design, CT cast technique, MT milling technique, SLM selective laser melting, for each preparation design “a” superscript letter indicate a statistically significant difference between CT and SLM and “A” superscript letter indicate a statistically significant difference between CT and MT (P ≤ 0.05 Bonferroni adjusted) 3. Statistical comparison of gap widths (U-test) with raw and adjusted (Bonferroni) P values ≤ 0.05

PD preparation design, SP standard preparation, OP preparation with occlusal isthmus, BP preparation with boxes, GP preparation with groves, CT cast technique, MT milling technique, SLM selective laser melting, n.s. not significant For the standard preparation design, significant differences between CT, MT, and SLM were only found for occlusal fit. The cast SC had significant better occlusal fit compared to SLM SC for medians of mean and maximal values.

For the preparation design with occlusal isthmus, significant differences between CT, MT, and SLM were found for occlusal fit and fit within auxiliary features. The cast SC had the smallest gap widths and significant better occlusal fit and fit within auxiliary features compared to SLM SC for medians of mean and maximal values.

For the preparation design with proximal boxes significant differences between CT, MT, and SLM were found for marginal and internal fit. Kruskal-Wallis test revealed significant differences for axial fit, occlusal fit and for fit within auxiliary features. The marginal and axial fit was significantly better for cast compared to milled SC for medians of mean and maximal values. Axial fit for cast compared to SLM SC was significant better only for medians of mean gap widths values. Cast SC had a significant better occlusal fit and fit within auxiliary features compared to milled and SLM SC and showed the smallest gap widths for medians of mean and maximal values.

For the preparation design with buccal/lingual grooves, significant differences between CT, MT, and SLM were showed for marginal and internal fit. Kruskal-Wallis test revealed significant differences for axial, occlusal and for fit within auxiliary features. The marginal and axial fit was significantly better for cast compared to milled SC for medians of mean and maximal values. For SLM SC axial gap widths were significantly higher than for cast SC only for medians of maximal values. Cast SC had a significant better occlusal fit and fit within auxiliary features compared to milled and SLM SC and showed the smallest gap widths for medians of mean and maximal values.

The percentage of SC with medians of mean and maximal values stated as clinically acceptable in this study is shown in Table 4.

4. Percent of SC within clinically acceptable gap widths stated for this study

SC single crown, PD preparation design, SP standard preparation, OP preparation with occlusal isthmus, BP preparation with boxes, GP preparation with groves, CT cast technique, MT milling technique, SLM selective laser melting, n.a. not applicable DISCUSSION

With regard to the results both null hypotheses had to be rejected partly or completely. SLM compared to cast SC showed a similar marginal fit for all designs tested. Contrary milled SC showed similar marginal fit to cast SC only in the standard preparation design and in the preparation design with the occlusal isthmus. Internal fit in all aspects was comparable only for standard preparation design and design with the occlusal isthmus between CT and MT.

In this study, the standard preparation design was included as a control for modified preparation designs with auxiliary features. Adding auxiliary features was conducted with the aim to maintain the resistance form of restorations [1–4]. Marginal gaps about 120 µm are described as clinically acceptable [17, 18]. Also, values up to 200 µm are described [38]. Most studies focused on marginal gaps and clinical acceptability. Internal occlusal gaps are described in some studies, but there is a lack of consent about the clinical influence and acceptability [15, 22, 24]. Meanwhile, there is a wide span of luting agents. Some studies show that different luting agents achieve different results according to retention depending on the internal gap [39]. For conventional cements (zinc phosphate) internal gaps up to 140 µm are described, nevertheless the reduction to 20 µm increases the retention up to 33% [20]. An increase of the internal gap up to 160 µm reduced the crown retention of self-etching dual-cure resin luting agents due to the possibility of incomplete polymerization. Therefore, May et al. recommended an occlusal precementation space of 50 µm to 100 µm for all-ceramic crowns with adhesive luting [21]. Especially in wide occlusal gaps the polymerization shrinkage can negatively influence the integrity of the adhesive luting film and thus decreases the failure load of all-ceramic crowns. Wiskott et al. showed that an increase in crown dislodgement resistance dependent on a decrease in the width of the cement layer [40]. Within the internal fit, the occlusal gap shows in various studies the highest values. There is a lack of studies about the influence of an occlusal gap on the longevity of restorations and inconsistency in recommendation for clinically acceptable range. Some authors described in vivo mean occlusal gap up to 350 µm as clinical acceptable [15, 24].

Summarizing, a median of mean internal fit (axial, occlusal and within auxiliary features) about 100 µm was assumed for this in vitro study as optimal and 160 µm as acceptable.

The SC with standard preparation design in this study revealed clinically acceptable marginal fit (< 120 µm) for all manufacturing techniques. In accordance with other studies, all tested systems can be seen as capable of producing crowns with clinically acceptable margins for standard preparation design [14, 15, 19]. According to the axial fit, the measured means and medians of mean gap widths were also clinically acceptable within the optimal range of about 100 µm. Contrary, the occlusal fit of SLM crowns was over the as optimal stated value. In our study, the highest mean and median of mean occlusal gap widths for the standard preparation design shows crowns in the SLM group. These results are similar to the measures of occlusal gaps for SLM restorations in other studies [7, 24]. Quante et al. interpreted them as acceptable, contrary to Nesse at al.[7, 24]. However, crowns described by Quante et al. with occlusal gaps between 250 to 350 µm were evaluated after 47 months and showed a low cumulative failure rate of 1.7%, with only one debonding [24]. Nevertheless, it has to be mentioned that the teeth treated in the study from Quante et al. had sufficient standard preparation design [24]. If approximately 100 to 160 µm is accepted as the optimal/acceptable occlusal gap, the values for SLM SC for standard preparation design are too high and could have a possibly negative clinical output. The influence of the wide occlusal gap can be even more pronounced in the teeth with compromised resistance/retentive form. This aspect needs further investigation, especially in longitudinal clinical trials.

The crowns for preparation design with occlusal isthmus showed a clinically acceptable fit at the margin (< 120 µm) and axial (< 100 µm) for all systems tested. Regarding the occlusal fit, the cast SC showed smallest gap widths (mean and maximal), the gap widths in milled SC were slightly wider and SLM SC were significantly wider. In addition, the gaps within the occlusal isthmus for the SLM SC were highly over the 100 to 160 µm and significantly worse than for cast SC. Nevertheless, the milled and SLM SC could be seated in their end position and had acceptable marginal and axial fit. The occlusal fit and fit within auxiliary features of SLM SC did not fulfill the optimum or acceptable requirements for occlusal fit in the present study (approximately 100 to 160µm), but depending on the different recommendations for occlusal fit, they could be seen as clinically acceptable from other authors. However, as for standard preparation design, the influence of wider gaps on crown resistance and retention in compromised teeth could be negative, especially for SLM crowns.

The crowns for preparation design with proximal boxes and buccal/lingual grooves showed acceptable marginal fit for cast and SLM SC. Milled SC did not show an acceptable marginal fit. Milled SC, within preparation designs with boxes or groves, showed particular poor fit and mostly could not be seated into their final position. Silicone replicas showed that the internal boxes or grooves got stuck in their preparation. For this reason, the values for internal and total internal fit are not representative and not discussed. All milled SC from tooth preparations with boxes or groves had to be judged as clinically unacceptable. For preparation designs with proximal boxes or buccal/lingual grooves, the casting technique achieves the smallest gap widths values (mean and maximal) regarding internal fit. SLM groups achieved a clinical optimal fit only at the margins; the axial gaps and gaps within boxes and grooves were slightly wider as 100–160 µm, and occlusal gaps considerably higher as 100–160 µm. In the design of the present study, such wide gaps could results in inadequate polymerization of adhesive cement if needed. Furthermore also gap widths values (mean and maximal) approximately over 180 µm within auxiliary features could result in functioning them inadequately. Although the SLM SC could be seated in their end position with an acceptable marginal fit, the functionality of the boxes and groves with as high gap widths is questionable. For this reason, the SLM system was stated as not capable of producing crowns with auxiliary features for increasing retention and as needed for further innovation.

Further studies are needed regarding the influence of internal fit especially of auxiliary features and occlusal fit on the resistance of crowns with compromised resistance form. In addition, the scanning and design parameters of the CAD/CAM process need further investigation.

CONCLUSIONS

Within the limitations of this study, regarding preparation designs with auxiliary features, only the casting technique was capable to produce single crowns with marginal and internal fit stated for this study as clinically acceptable. CAD/CAM systems did not produce clinically sufficient results and need further improvement.

Acknowledgement

The authors thank BEGO Medical GmbH and Noble Biocare for providing CAD/CAM crowns.

Corresponding author

Dr. med. dent. Katarzyna Walczak

Department of Prosthetic Dentistry, Carl Gustav Carus Faculty of Medicine

Technische Universität Dresden

Fetscherstr. 74, 01307 Dresden

Germany

Sources

1. Gilboe DB, Teteruck WR. Fundamentals of extracoronal tooth preparation. Part I. Retention and resistance form. J Prosthet Dent. 2005; 94(2): 105–107. doi.org/10.1016/j.prosdent.2005.02.018.

2. Goodacre CJ, Campagni WV, Aquilino SA. Tooth preparations for complete crowns: An art form based on scientific principles. J Prosthet Dent. 2001; 85(4): 363–376. doi.org/10.1067/mpr.2001.114685.

3. Lu PC, Wilson P. Effect of auxiliary grooves on molar crown preparations lacking resistance form: a laboratory study. J Prosthodont. 2008; 17(2): 85–91. doi:10.1111/j.1532-849X.2007.00263.x.

4. Naik VA, Jurel SK. Comparative analysis of auxiliary retentive factors affecting retention of complete cast metal crown. Int J Stomatol Occlusion Med. 2010; 3(4): 195–199. doi:10.1007/s12548-011-0070-z.

5. Papadiochou S, Pissiotis AL. Marginal adaptation and CAD-CAM technology: A systematic review of restorative material and fabrication techniques. J Prosthet Dent. 2018; 119(4): 545–551. doi:10.1016/j.prosdent.2017.07.001.

6. Oilo M, Nesse H, Lundberg OJ, Gjerdet NR. Mechanical properties of cobalt-chromium 3-unit fixed dental prostheses fabricated by casting, milling, and additive manufacturing. J Prosthet Dent. 2018; 120(1): 156.e151–156.e157. doi:10.1016/j.prosdent.2017.12.007.

7. Nesse H, Ulstein DMÅ, Vaage MM, Øilo M. Internal and marginal fit of cobalt-chromium fixed dental prostheses fabricated with 3 different techniques. J Prosthet Dent. 2015; 114(5): 686–692. doi.org/10.1016/j.prosdent.2015.05.007.

8. Davidowitz G, Kotick PG. The use of CAD/CAM in dentistry. Dental Clin. 2011; 55(3): 559–570.

9. Ahmed KE. We're going digital: the current state of CAD/CAM dentistry in prosthodontics. Prim Dent J, 2018; 7(2): 30–35.

10. Sun J, Zhang FQ. The application of rapid prototyping in prosthodontics. J Prosthodont. 2012; 21(8): 641–644.

11. Miyazaki T, Hotta Y. CAD/CAM systems available for the fabrication of crown and bridge restorations. Aust Dent J. 2011; 56, Suppl. 1 : 97–106. doi:10.1111/j.1834-7819.2010.01300.x.

12. Alghazzawi TF. Advancements in CAD/CAM technology: Options for practical implementation. J Prosthodont Res. 2016; 60(2): 72–84. doi:10.1016/j.jpor.2016.01.003.

13. Koutsoukis T, Zinelis S, Eliades G, Al-Wazzan K, Rifaiy MA, Al Jabbari YS. Selective laser melting technique of co-cr dental alloys: A review of structure and properties and comparative analysis with other available techniques. J Prosthodont. 2015; 24(4): 303–312. doi:10.1111/jopr.12268.

14. Gunsoy S, Ulusoy M. Evaluation of marginal/internal fit of chrome-cobalt crowns: Direct laser metal sintering versus computer-aided design and computer-aided manufacturing. Niger J Clin Pract. 2016; 19(5): 636–644. doi:10.4103/1119-3077.188699.

15. Huang Z, Zhang L, Zhu J, Zhao Y, Zhang X. Clinical marginal and internal fit of crowns fabricated using different CAD/CAM technologies. J Prosthodont. 2015; 24(4): 291–295. doi:10.1111/jopr.12209.

16. Tara MA, Eschbach S, Bohlsen F, Kern M. Clinical outcome of metal-ceramic crowns fabricated with laser-sintering technology. Int J Prosthodont. 2011; 24(1): 46–48.

17. Fransson B, Oilo G, Gjeitanger R. The fit of metal-ceramic crowns, a clinical study. Dent Mater. 1985; 1(5): 197–199.

18. McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971; 131(3): 107–111.

19. Papadiochou S, Pissiotis AL. Marginal adaptation and CAD-CAM technology: A systematic review of restorative material and fabrication techniques. J Prosthet Dent. 2017; 119(4): 545–551. doi:10.1016/j.prosdent.2017.07.001.

20. Jorgensen KD, Esbensen AL. The relationship between the film thickness of zinc phosphate cement and the retention of veneer crowns. Acta Odontol Scand. 1968; 26(3): 169–175.

21. May LG, Kelly JR, Bottino MA, Hill T. Effects of cement thickness and bonding on the failure loads of CAD/CAM ceramic crowns: Multi-physics FEA modeling and monotonic testing. Dent Mater. 2012; 28(8): 99–109. doi.org/10.1016/j.dental.2012.04.033.

22. Tamac E, Toksavul S, Toman M. Clinical marginal and internal adaptation of CAD/CAM milling, laser sintering, and cast metal ceramic crowns. J Prosthet Dent. 2014; 112(4): 909–913. doi.org/10.1016/j.prosdent.2013.12.020.

23. Huang Z, Zhang L, Zhu J, Zhang X. Clinical marginal and internal fit of metal ceramic crowns fabricated with a selective laser melting technology. J Prosthet Dent. 2015; 113(6): 623–627. doi:10.1016/j.prosdent.2014.10.012.

24. Quante K, Ludwig K, Kern M. Marginal and internal fit of metal-ceramic crowns fabricated with a new laser melting technology. Dent Mater. 2008; 24(10): 1311–1315.

25. Castillo-Oyagüe R, Lynch CD, Turrión AS, López-Lozano JF, Torres-Lagares D, Suárez-García MJ. Misfit and microleakage of implant-supported crown copings obtained by laser sintering and casting techniques, luted with glass-ionomer, resin cements and acrylic/urethane-based agents. J Dent. 2013; 41(1): 90–96. doi.org/10.1016/j.jdent.2012.09.014.

26. Dahl BE, Ronold HJ, Dahl JE. Internal fit of single crowns produced by CAD-CAM and lost-wax metal casting technique assessed by the triple-scan protocol. J Prosthet Dent. 2017; 117(3): 400–404. doi:10.1016/j.prosdent.2016.06.017.

27. Kim EH, Lee DH, Kwon SM, Kwon TY. A microcomputed tomography evaluation of the marginal fit of cobalt-chromium alloy copings fabricated by new manufacturing techniques and alloy systems. J Prosthet Dent. 2016; 117(3): 393–399. doi:10.1016/j.prosdent.2016.08.002.

28. Kim KB, Kim WC, Kim HY, Kim JH. An evaluation of marginal fit of three-unit fixed dental prostheses fabricated by direct metal laser sintering system. Dent Mater. 2013; 29(7): 91–96.

29. Myszka D, Skrodzki M. Comparison of dental prostheses cast and sintered by SLM from Co-Cr-Mo-W alloy. Arch Foundry Eng. 2016; 16(4): 201–207.

30. Örtorp A, Jönsson D, Mouhsen A, von Steyern PV. The fit of cobalt–chromium three-unit fixed dental prostheses fabricated with four different techniques: A comparative in vitro study. Dent Mater. 2011; 27(4): 356–363.

31. Pompa G, Di Carlo S, De Angelis F, Cristalli MP, Annibali S. Comparison of conventional methods and laser-assisted rapid prototyping for manufacturing fixed dental prostheses: An in vitro study. Biomed Res Int. 2015 : 318097. doi:10.1155/2015/318097.

32. Suleiman SH, Vult von Steyern P. Fracture strength of porcelain fused to metal crowns made of cast, milled or laser-sintered cobalt-chromium. Acta Odontol Scand. 2013; 71(5): 1280–1289. doi:10.3109/00016357.2012.757650.

33. Tuna SH, Özçiçek Pekmez N, Kürkçüoğlu I. Corrosion resistance assessment of Co-Cr alloy frameworks fabricated by CAD/CAM milling, laser sintering, and casting methods. J Prosthet Dent. 2015; 114(5): 725–734. doi.org/10.1016/j.prosdent.2015.02.031.

34. Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent. 2009; 102(4): 253–259. doi:10.1016/s0022-3913(09)60165-7.

35. Zeng L, Xiang N, Wei B. A comparison of corrosion resistance of cobalt-chromium-molybdenum metal ceramic alloy fabricated with selective laser melting and traditional processing. J Prosthet Dent. 2014; 112(5): 1217–1224. doi:http://dx.doi.org/10.1016/j.prosdent.2014.03.018.

36. Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989; 62(4): 405–408.

37. Boening KW, Wolf BH, Schmidt AE, Kastner K, Walter MH. Clinical fit of procera allceram crowns. J Prosthet Dent. 2000; 84(4): 419–424. doi:10.1067/mpr.2000.109125.

38. Bjorn AL, Bjorn H, Grkovic B. Marginal fit of restorations and its relation to periodontal bone level. II. Crowns. Odontol Rev. 1970; 21(3): 337–346.

39. Son YH, Han CH, Kim S. Influence of internal-gap width and cement type on the retentive force of zirconia copings in pullout testing. J Dent. 2012; 40(10): 866–872. doi.org/10.1016/j.jdent.2012.07.007.

40. Wiskott HW, Belser UC, Scherrer SS. The effect of film thickness and surface texture on the resistance of cemented extracoronal restorations to lateral fatigue loading. Int J Prosthodont. 1999; 12(3): 255–262.

Labels

Maxillofacial surgery Orthodontics Dental medicine

Article was published inCzech Dental Journal

2020 Issue 3-

All articles in this issue

- Sto let od úmrtí Eduarda Nessela

- EFFECT OF LOW, MEDIUM AND HIGH MOLECULAR WEIGHT HYALURONIC ACID ON HUMAN DENTAL PULP STEM CELLS

- THE MARGINAL AND INTERNAL FIT OF COCR ALLOY SINGLE CROWNS WITH PREPARATION DESIGNS INCLUDING AUXILIARY FEATURES; CAD/CAM VERSUS CONVENTIONAL TECHNIQUE

- Editorial

- UNICONE PLUS VS. UNICONE – IN VITRO CYCLIC FATIGUE STUDY AT DIFFERENT ENVIROMENTAL TEMPERATURES

- Vzpomínka na profesora Eduarda Nessela

- Czech Dental Journal

- Journal archive

- Current issue

- Online only

- About the journal

Most read in this issue- THE MARGINAL AND INTERNAL FIT OF COCR ALLOY SINGLE CROWNS WITH PREPARATION DESIGNS INCLUDING AUXILIARY FEATURES; CAD/CAM VERSUS CONVENTIONAL TECHNIQUE

- EFFECT OF LOW, MEDIUM AND HIGH MOLECULAR WEIGHT HYALURONIC ACID ON HUMAN DENTAL PULP STEM CELLS

- UNICONE PLUS VS. UNICONE – IN VITRO CYCLIC FATIGUE STUDY AT DIFFERENT ENVIROMENTAL TEMPERATURES

- Vzpomínka na profesora Eduarda Nessela

Login#ADS_BOTTOM_SCRIPTS#Forgotten passwordEnter the email address that you registered with. We will send you instructions on how to set a new password.

- Career