-

Medical journals

- Career

Evaluation of compressibility of tableting mixtures using the compaction equation

Authors: Pavel Ondrejček; Petra Svačinová; Jan Stoniš; Zdenka Šklubalová; Miloslava Rabišková

Authors‘ workplace: Charles University in Prague, Faculty of Pharmacy, Department of Pharmaceutical Technology, Hradec Králové, Czech Republic

Published in: Čes. slov. Farm., 2015; 64, 189-191

Category:

Introduction

Tablets as a pharmaceutical dosage form are most commonly made by compaction of the same volumes of powders or granulates. It is necessary to evaluate the properties of the mentioned materials used for the preparation of tablets. These properties include e.g. the moisture content, flow properties, the particle size distribution, compressibility, and compactibility.

The main aim of this work was to evaluate the usability of the compaction equation [1] in the description of the effect of two selected lubricants on the compressibility of tableting mixtures of α-lactose monohydrate. The study of the relations between the parameters of the compaction equation and the results of mass flow rate, Hausner ratio, and the tablet tensile strength were the further aim.

Experimental methods

Materials and methods

Sieved α-lactose monohydrate Lactochem Fine Crystals (Lactochem) was used as the filler. Hydrophobic sodium stearyl fumarate PRUV (PRUV) and/or hydrophilic modified colloidal silicon dioxide Syloid FP 244 EU (Syloid), respectively, in the concentration of 0.5% were used as lubricants.

Particle size distribution was determined using a Malvern Mastersizer. A Quantachrome Instruments Nova Station A was used for the measurement of the specific surface area and a scanning electron microscope MIRATESCAN (TESCAN) was used for the observation of the particle shape and the surface. Moisture content was measured using a moisture analyser Kern MLB 50-3.

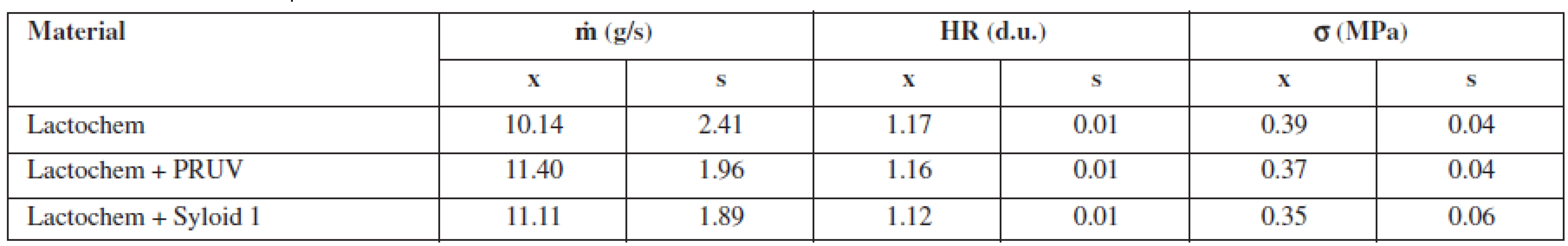

The tableting mixtures were prepared using a cube blender Erweka (AR401 + KB15S). The flow properties of the filler and the mixtures were evaluated using an Erweka GTB instrument (200 ml stainless steel conical hopper with a 10 mm outlet nozzle) and a tapped density tester Erweka SVM 102. The average of ten measurements is shown in Table 1 including the standard deviation s.

Compaction equation

A material testing machine Zwick/Roell T1 FRO 50 was used for the compaction of tablets with the mass of 500 mg and 13 mm in diameter, and for the measurement of their strength according to Fell and Newton1). Compaction was carried out at the compaction force of 40 kN.

To evaluate the compaction process and to compare the tableting mixtures, the compaction equation [1] was used2):

where V is the volume (mm3) of the compacted material at the current compaction pressure p (MPa). V0 is the volume of the compacted material (mm3) at zero pressure (MPa). The equation (1) has parameters which can be estimated from the relationship between the volume reduction of a tableting material and the compaction pressure. The parameter ai (d.u.) describes the theoretical maximal volume reduction of a tableting material at a particular phase of the compression process, the parameter 1/ti (a slope) describes the speed of the volume reduction at a particular phase (MPa–1), and the parameter y0 (d.u.) describes the maximal theoretical volume reduction at the infinite compaction pressure. In order to study the influence of the excipients on the compaction process, the parameters ai and 1/ti are useful.

The parameters of the compaction equation can be used for the calculation of the energy Ei (J) used during a compaction process in a particular phase. These energetic parameters can be calculated according to equation [2], where all symbols have the same meaning as those mentioned above:

Analysis of variance (ANOVA) was used to test the significance of the lubricants effect on the parameters of the compaction equation.

Results and discussion

Flow properties

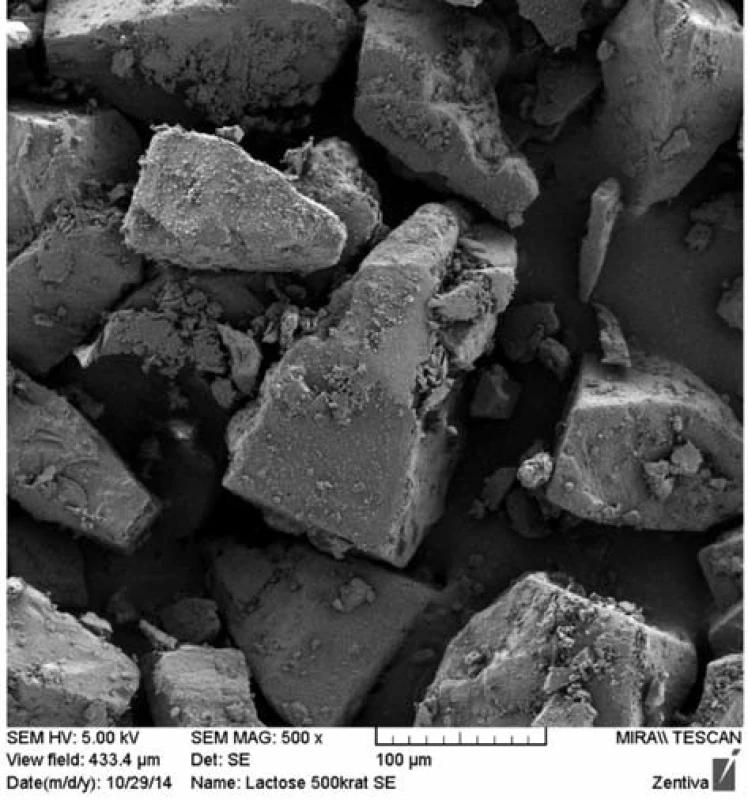

Figure 1 illustrates the regularly shaped, smooth crystals of αα-lactose monohydrate.

1. SEM image of α-lactose monohydrate Lactochem Fine Crystals

The results of the flow properties measurements are summarized in Table 1. An increase in the mass flow rate and a decrease in Hausner ratio after an addition of hydrophobic PRUV and/or hydrophilic Syloid, respectively, is seen. The lubricants improve the flow properties of the particulate material by forming a film on the surface of filler particles3). All samples had good flow properties.

1. Mass flow rate (ṁ), Hausner ratio (HR) and tablet tensile strength (σ)

Compaction equation

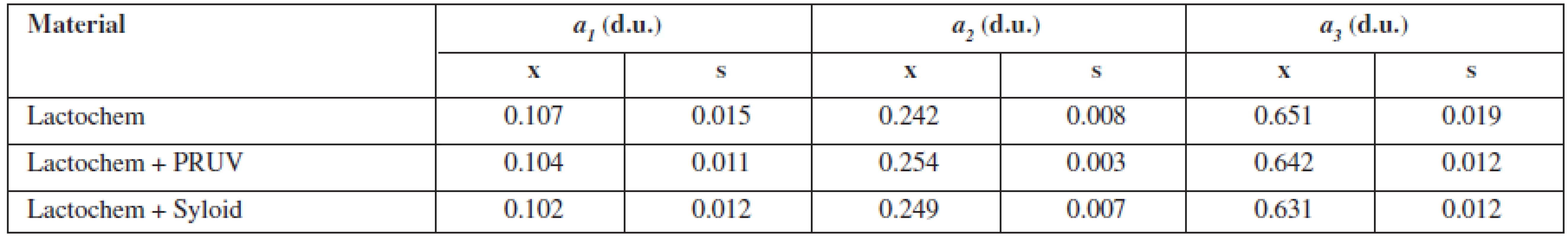

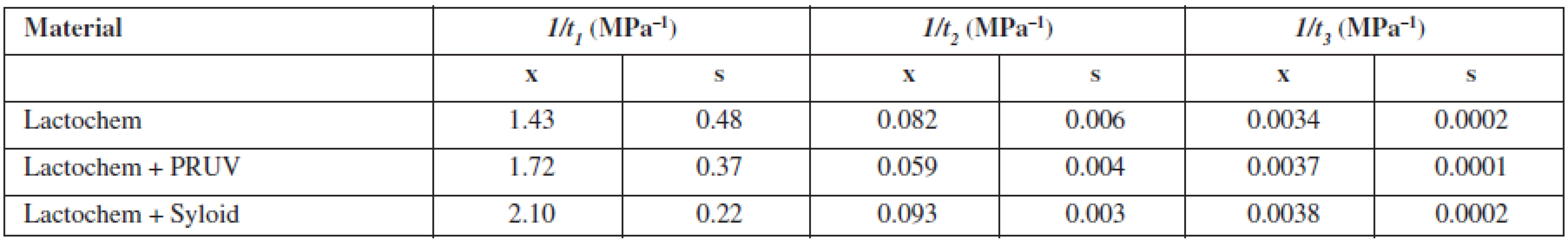

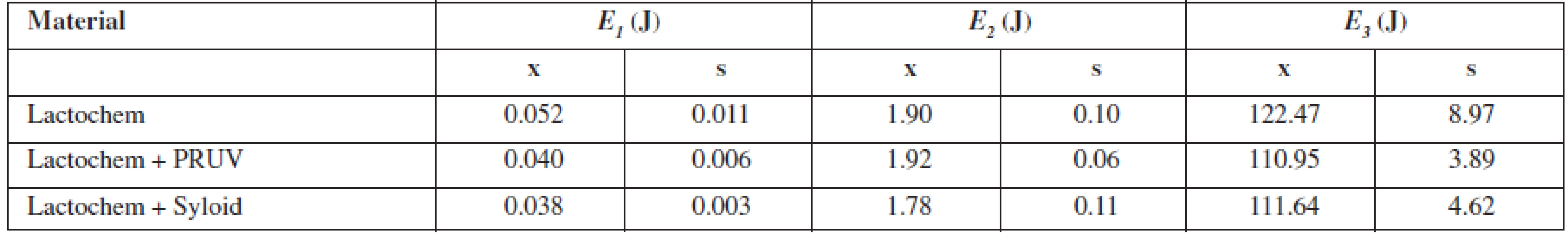

The three-exponential equation [1] similar to Cooper-Easton’s equation4) was developed for the evaluation of the pharmaceutical materials2, 5). This equation divides the compaction process into three simultaneously running phases. The first one describes the precompression that includes the particle rearrangement, the interparticulate friction and the friction between the material and the walls of the die. The second particular process characterizes the elastic deformation of the particles. In the third phase of the process, the plastic deformation of the compacted material is described. The parameters of the compaction equation [1] are summarized in Tables 2, 3 and 4.

2. The a<sub>i</sub> parameters of tableting materials

3. The l/t<sub>i</sub> parameters of tableting materials

4. The energetic parameters of tableting materials

The results show that an addition of both lubricants decreases the volume reduction in the precompression phase (a1), speeds it up (l/t1) and decreases the energy consumption (E1). These parameters are affected by the volume of material before compaction, which depends on its flow and compressibility properties.

Lubricants generally facilitate the particle rearrangement of a powder material and decrease the difference between the bulk and the tapped volume. The lower is the volume of material before compaction, the faster is the volume reduction and less energy is consumed for the precompression phase.

The phase of elastic deformation is affected mainly by the filler type. The brittle Lactochem with very low elasticity fragments easily when compressed and forms weak van der Waals bonds. The noted effect of lubricants on the parameters of the phase of elastic deformations (a2, l/t2, E2) was insignificant (p = 0.05).

The phase of plastic deformation is the most important part of the compaction process. Being a brittle material, Lactochem tends to fragment repeatedly during the compaction. This fragmentation is connected with the creation of new bonds and surfaces6). In comparison with Lactochem itself, the values of the volume reduction a3 and the consumed energy for compaction E3 were lower, and the process was faster in the presence of lubricants.

The film of lubricants on the particle surface, generally, can affect the properties of tablets, particularly their tensile strength. The tablets prepared from the mixtures had a lower σ (MPa) than the tablets made from Lactochem itself as is shown in Table 1.

Although the energy consumed in the third phase E3 was almost the same for both lubricants used, a difference in the tensile strength was observed. This may be caused by the difference in the specific surface area and the particle size of the lubricants. The measured specific surface area was 1.62 m2/g for PRUV and 274.48 m2/g for Syloid, respectively. This corresponds to smaller particle size diameters of Syloid Dv,10 = 1.87 μm, Dv,50 = 3.52 μm, and Dv,90 = 7.43 μm when compared with those found for PRUV Dv,10 = 5.39 μm, Dv,50 = 17.16 μm, and Dv,90 = 39.52 μm. These two factors can greatly affect the lubricant activity7).

Conclusions

Based on the results, the used compaction equation is suitable for the evaluation of compressibility behaviour of αα-lactose monohydrate and its mixtures with the lubricants during the direct compression process. Correlations were found between the parameters of flow properties (ṁ and HR) and the parameters a1, l/t1 and E1 of the compaction equation which describes the first phase of the compaction process, i.e. the precompression phase. However, more experiments are necessary to make general conclusions. The relations between the energetic parameter E3 and the tensile strength σ of tablets will be further investigated.

The authors thanks are due to the specific research project SVV 260 183 of Charles University in Prague for the financial support.

Conflicts of interest: none.

Mgr. Pavel Ondrejček

Charles University, Faculty of Pharmacy

Heyrovského 1203, 500 05 Hradec Králové, Czech Republic

e-mail: ondrp3aa@faf.cuni.cz

Sources

1. Fell J. T., Newton J. M. Determination of tablet strength by the diametral-compression test. J. Pharm. Sci. 1970; 59, 688–691.

2. Řehula M., Rysl T. Characterization of microcrystalline celluloses by means of the parameters of a three-exponential compression equation. Ces. slov. Farm. 2008; 57, 165–169.

3. Li J., Wu Y. Lubricants in pharmaceutical solid dosage forms. Lubricants 2014; 2, 21–43.

4. Cooper A. R., Eaton L. E. Compaction behavior of several ceramic powders. J. Am. Ceram. Soc. 1962; 45, 97–101.

5. Ondrejček P., Řehula M., Svačinová P., Stoniš J., Rabišková M. The effect of a new glidant Syloid on pressing of drug tablets. Chem Listy 2014; 108, 687–693.

6. Eriksson M., Alderborn G. The effect of particle fragmentation and deformation on the interparticulate bond formation process during powder compaction. Pharm. Res. 1995; 12, 1031–1039.

7. Wang J., Wen H., Desai D. Lubrication in tablet formulations. Eur. J. Pharm. Biopharm. 2010; 75, 1–15.

Labels

Pharmacy Clinical pharmacology

Article was published inCzech and Slovak Pharmacy

2015 Issue 5-

All articles in this issue

- Methods used in pharmaceutical technology to increase bioavailability of poorly soluble drugs after oral administration

- Level and factors influencing the patients’ satisfaction with the pharmaceutical care in Slovakia

- Drugs and health care expenditure on the aging population

- Drug bioavailability increasing by formulation of liquisolid systems

- Evaluation of compressibility of tableting mixtures using the compaction equation

- Branched polyesters as mucoadhesive carriers of drugs

- Evaluation of water absorption rate of tablets by using an Enslin-Neff device

- Evaluation of the influence of lubricants on the viscoelastic properties of tablets using the stress relaxation test

-

44th Conference drug synthesis and analysis

(Brno, 2nd to 4th September 2015) – Part 1 - Determination of biologically active compounds in the fungi of the genus Cordyceps sinensis by HPLC and NMR

- Determination of CMC of cationic tenside in aqueous and mixed water-alcohol solutions

- A comparison of SiO2-, Cu-, and Ni-supported Au nanoparticles for selective glycerol oxidation to acetic acid*

- Determination of acid-base dissociation constants of newly synthesized arylethanolamine derivatives using capillary zone electrophoresis

- HPLC method for stability evaluation of pharmaceutical preparations containing sodium picosulfate

- The use of 2,6-dichloroquinone-4-chlorimide for quantitative determination of phenylephrine hydrochloride in combined tablets with paracetamol and chlorpheniramine maleate

- The utilization of radionuclide X-ray spectrometry in the determination of elements in medicinal plants and medicinal products used as antianemics

- On-line hyphenated capillary electrophoresis and tandem mass spectrometry used for the analysis of selected biogenic amines in grape leaves

- Validation of spectrophotometric methods of assaying metronidazole in capsules

- Czech and Slovak Pharmacy

- Journal archive

- Current issue

- Online only

- About the journal

Most read in this issue- Methods used in pharmaceutical technology to increase bioavailability of poorly soluble drugs after oral administration

- Level and factors influencing the patients’ satisfaction with the pharmaceutical care in Slovakia

- HPLC method for stability evaluation of pharmaceutical preparations containing sodium picosulfate

- The use of 2,6-dichloroquinone-4-chlorimide for quantitative determination of phenylephrine hydrochloride in combined tablets with paracetamol and chlorpheniramine maleate

Login#ADS_BOTTOM_SCRIPTS#Forgotten passwordEnter the email address that you registered with. We will send you instructions on how to set a new password.

- Career